TECH Q & A (FAQ’s)

|

|

||||||||||||||||||||||||||||||

|

“The man of science has learned to believe in justification, A fire alarm Verification is a highly specialized test performed on a fire alarm system in accordance with CAN/ULC-S537 (Standard for Verification of Fire Alarm Systems) by an individual that can demonstrate knowledge of the referenced Standard, the Canadian Electrical Code, the Building Code, and has both the training and experience recognized and accepted by the local jurisdictional authority. IMPORTANT: LINK CHANGES FOR CITY OF VANCOUVER WEBSITE The City of Vancouver’s website has recently undergone a major upgrade. Many links to Bulletins from our website will, as a result, now display a custom error page. If you happen to come across this, simply type former. (the dot is important) ahead of vancouver in your browser’s address bar, and it should open the proper document. We’ll endeavour to update all of our links once the City’s Web-Minions get finished with fixing all of theirs! |

|||||||||||||||||||||||||||||||

|

As you navigate through the various FAQ pages on our site, you’ll notice that we’ve provided handy pointers that highlight information which might be of special interest in the answers we’ve provided. Look for these symbols in the right hand margin:

|

|||||||||||||||||||||||||||||||

|

FIRE ALARM VERIFICATION FAQ: How do you Verify the installation of fire alarm isolator modules? Where can I download a Fire Alarm Verification Certificate? What fire alarm verification tests are required? How many fire alarm speakers need to be verified when expanding a circuit? When is a Verification required? When did CAN/ULC-S537-04 actually come into effect? |

|||||||||||||||||||||||||||||||

|

What standard do I use in verifying a fire alarm system that was installed thirty years ago? Should a Verification Inspection be carried out on a system that you know to be non-compliant (or that you know will "fail" even before you start)? How can a local authority properly vet (authenticate) a fire alarm system verification report? Who has final authority to accept a fire alarm system installation? Which code references CAN/ULC-S537 (Standard for Verification of Fire Alarm Systems) thereby making it a legal document? Who can verify a fire alarm system (in Canada)? What qualifications should they have? Can the installation company (or contractor) "sign off" on the Verification? UPDATED! How many times is a fire alarm system verified? I'm concerned with the attached fire alarm Verification Report. It doesn't remotely resemble another report we received on a similar project we manage in Burnaby. What should we do, and whom do we contact to give us the proper information? What is a Fire Alarm Verification Certificate? What should a Fire Alarm Verification Test Report (CAN/ULC-S537 Appendix “C”) include? If I change out a fire alarm device, do I need a verification? |

|||||||||||||||||||||||||||||||

|

|

|

||||||||||||||||||||||||||||||

|

What fire alarm verification tests are required? The tests required depends on what is being verified and why. If it's a new fire alarm installation, then the answer is quite simply "everything". If it's an addition to the system (new initiating device or notification appliance) then Section 7 of the 2013 published edition of the Standard applies (it’s Section 27 in the 2019 Version that is going to be coming into effect in most jurisdictions shortly). Regardless of what field device you're verifying you must ensure the control panel's power supply is up to the task (and while you're at it, feel free to comment on anything you might see that's out of the ordinary). As a verifier, your observations carry a great deal more weight and could provide helpful guidelines for the local AHJ to follow up on when the building owner is contemplating an upgrade. |

|

||||||||||||||||||||||||||||||

|

How many fire alarm speakers need to be verified when expanding a circuit? I just love the easy answers! All of the speakers in the affected circuit will have to be verified. Section 7 of the 2013 published edition of the Verification Standard (it’s Section 27 in the new 2019 version) deals with something called "System Modifications". CAN/ULC-S537-13 Clause 7.4 reads: “Where a conventional field device is added, or modifications or deletions are made to an existing input circuit or output circuit, and the new, modified or altered wiring is extended from a junction box, all devices served by that circuit shall be verified in accordance with this Standard.” CAN/ULC 537:2019 Clause 27.4 is worded identically. |

|

||||||||||||||||||||||||||||||

|

Who can verify a fire alarm system (in Canada)? What qualifications should they have? Can the installation company (or contractor) "sign off" on the Verification? AHJ's all across Canada have been deliberating over the definitive answer to this question for years. CAN/ULC-S537-13 states that the Verification must be carried out by an agency (or individual) acceptable to the Authority Having Jurisdiction, who can demonstrate they have the sufficient training or experience, and who is not the installing contractor or involved in the design of the fire alarm system. CFAA has published a position paper on the subject which attempts to establish the means by which an AHJ might formulate their own criteria, but it incorrectly suggests that only manufacturer trained technicians should perform Verifications “... where the system is of addressable design, software driven, or is a networked system...”. It is a sad fact that some manufacturer trained technicians are often ill prepared to actually identify even their own incorrectly installed fire alarm equipment (or the required wiring), let alone flag an installation as unacceptable which might jeopardize an established business relationship with the contractor (or the Registered Professional) under whose auspices they may have been contracted. It has been our experience that a good proportion of them are more concerned with ensuring the system is properly programmed (the software required has become even more complex partly as a result of the introduction of "mass notification" requirements and the firmware changes this has prompted). Manufacturer training should not automatically qualify a technician to perform a Verification! While the system software can undergo a form of programming verification, or program checking , the training that is provided by many manufacturers should not be confused with the required knowledge of the Standard, the various Codes and local Bylaws that are the means by which a fire alarm system installation is confirmed as having been installed correctly in accordance with CAN/ULC-S524 and the design. The Standard for Verification of Fire Alarm Systems does not specifically identify anything that is manufacturer specific in the suitable formal training required of a qualified individual (in point of fact it would be ILLEGAL for any Canadian Standard to do so). “This Standard expects that the verification procedure described herein will be conducted and documented in accordance with the administrative requirements stipulated by jurisdictional regulations and the Authority Having Jurisdiction. It is recognized that the designer is often an engineering professional independent from the installing contractor and the qualified individual conducting the verification. Jurisdictional requirements and the Authority Having Jurisdiction should be consulted to determine the requirements of qualifications and professional independence of the system designer, installing contractor and the individual conducting the verification. Regulations and the AHJ may require that a fire alarm system is designed by, and reviewed, and signed by a professional engineer. In case where professional engineering involvement is not explicitly required by jurisdictional requirements and in the absence of acceptance criteria established by the AHJ, the verification may be conducted by an organization other than the installing contractor and designer, as long as it is carried out by qualified personnel in the employ of an organization acceptable to the authority having jurisdiction. Any person who performs the verification of a fire alarm system is to be familiar with this Standard and have received suitable formal training or sufficient experience acceptable to the authority having jurisdiction. Many local authorities have adopted their own criteria when it comes to designating approved Verification agencies and acceptable individuals (we cover some of these on our TOOLS page). The City of Vancouver had, up until last year, taken the lead in this issue and defined not only the minimum acceptance criteria, but had actually listed individuals and organizations whom they deemed to be acceptable to provide commissioning and verification of fire alarm systems in their Bulletin 2003-009-EL. They have since decided to offload the selection of the qualified Verifier, along with the acceptance of the properly formatted Appendix “C” documentation, to the Registered Professional that’s mandated to provide the NBCC required Schedule “CB” on a building project (this is further detailed in this April 2017 Tech-News article). Membership in a professional organization like CFAA or ASTTBC may provide some additional recognition, but until these organizations start supporting the individuals they certify, and provide the means to rigorously police their membership, Verification inspections will continue to fall short of the Standard for the reasons we’ve already articulated here (as well as in several EDITORIALS and Tech-News Features). We've suggested several means to help an AHJ in determining the means to "vet" a verification test report. You can explore these options here and here. ULC has also issued a Standards Bulletin which may prove helpful as well. The Fire Technicians Network National Certification Programme (launched in March of 2017), provides a new benchmark for technician practice in Canada. Concurrent to the Programme’s launch is an expanded lab-based and online training initiative that features the ONLY dedicated Fire Alarm Verification Courses currently available. If your company has performed (or has been approved by the local jurisdictional authority to provide) a verification and you have been contracted to provide the installation of the fire alarm equipment, you (and your company) are ineligible to verify the system. Even if you subcontract the physical installation work to another agency (who may have pulled the necessary permits), you are still viewed as the primary contractor. Some jurisdictions require the contractor to sign off in an assisting capacity to the actual verification agency. It is extremely important to recognize that an arms length relationship must be maintained between the individual (or company) performing the verification and the installing contractor. |

|

||||||||||||||||||||||||||||||

|

When is a Verification Required? When-ever a new fire alarm system is installed is the "simple" answer, but there are many more instances where a Verification is required. When-ever you make a material change or alteration to an existing fire alarm system a Verification must follow. This includes changing a defective field device with a new one, adding a new field device, changing out a remote annunciator, common control, or power supply. If you replace a card or plug-in board in the common control any affected circuits MUST be verified. When changing a defective field device where wiring is not disturbed or has to be disconnected (as is the case with smoke and heat detectors that incorporate "plug-in" style bases), an actual report documenting the Verification isn't required. In all other instances, you must follow the procedures outlined in Section 7 of CAN/ULC-S537-13 (Section 6 of CAN/ULC-S537-04) without exception. Additional information is available in this FAQ. |

|

||||||||||||||||||||||||||||||

|

I'm testing a building with System Sensor C2W-BA smoke detectors installed. Does observation of the LED flash pattern and comparing it to the table in the installation instructions constitute "Sensitivity Testing" as defined in the Standard? Yes! Clause 5.7.4.1.6 of CAN/ULC-S536-04 (5.4.1.6 of CAN/ULC-S537-04) states: “Acceptable methods of determining the smoke detector sensitivity are: A) Manufacturer's recommended test instrument, equipment, or method;...” The key word in this sentence is “method”. |

|

||||||||||||||||||||||||||||||

|

When did CAN/ULC-S537-04 (Canadian Fire Alarm Verification Standard) or CAN/ULC-S536-04 (Canadian Inspection Standard for Fire Alarm Systems) actually come into effect? The latest of ANY Standard comes "into effect" with the publication of the newest Code release. In British Columbia, both the BC Building Code and the BC Fire Code were substantially amended in 2012. This would make the "04" edition of CAN/ULC-S537 (CAN/ULC-S536) the one to go on. The Installation Standard (CAN/ULC-S524) that’s referenced is the the December 2006 version. I think you'll find that most Authorities however, have adopted the CAN/ULC-S524-06 - Including Amendment 1 - regardless (at least those that I've spoken to). You should check with the local Authority Having Jurisdiction to see which version of this particular Standard they're going to be referencing. UPDATE: In British Columbia (and other Provinces), the National Building Code now being referenced is the 2010 version. BC’s Building Code 2012 was formally adopted in December of 2012. Both NBC and BCBC now officially reference CAN/ULC-S524-06 and CAN/ULC-S537-04. We have provided AMENDED Verification Forms which address the additional testing requirements made necessary by the changes in the Installation Standard in the FORMS area of our LIBRARY. UPDATE: Alberta has adopted NBC 2010 and NFC 2010 as their Alberta Building Code 2014 and Alberta Fire Code 2014 (respectively). The Verification Standard referenced in the ABC is CAN/ULC-S537-13. The Inspection Standard referenced in the AFC is CAN/ULC-S536-13. You can download versions of BOTH Standards from our FORMS page. UPDATE: A number of provinces and jurisdictions have adopted (or are on the cust of adopting) the 2020 National Building Code (which at this time is also undergoing a formal public review). Check with your jurisdiction to confirm which Standards apply to your project. Our members are REQUIRED to utilize the 2019 published editions of CAN/ULC 536 and CAN/ULC 537, both of which can be downloaded from our FORMS page. |

|

||||||||||||||||||||||||||||||

|

What standard do you use when verifying a fire alarm system that was installed thirty years ago? Most of the manual stations are installed well above 1400mm and there are heat detectors mounted on the wall. In Canada, there is only one installation Standard. It's called CAN/ULC-S524. The Verification Standard (CAN/ULC-S537) is the testing standard. It references the former. You MUST test to both these Standards and ensure that you note any deficiencies or deviations from them. It is not within your job description to amend or interpret what you see in the field to fit a given situation. You must not ignore deviations from the standards! Your job is to VERIFY TO THE STANDARDS indicated above (and any appropriate sections of the building and electrical codes). In many older structures, the back boxes were not individually bonded to ground (only two wires - often two conductor 18AWG LVT - was run). Some buildings still utilize a three-wire unsupervised 12 (or 24) volt relay box as a fire alarm control. This unit almost invariably self resets when the alarm initiating device is restored to normal. One manufacturer's senior service rep once advised me that they verify to the engineer's drawings. CAN/ULC-S537 not only references the engineer's drawings (or design)! It references BOTH the design and CAN/ULC-S524. Keep in mind that the Verification is the single most important test a fire alarm SYSTEM will have to undergo in its lifetime. It ensures that the SYSTEM has been installed AND DESIGNED correctly and identifies those deviations from code in older systems that will help the local authority make recommendations (or draft orders) for improvement. This relegates the Verifier to a singularly important role. You are the local jurisdictional authorities watchdog. Our November 2012 Editorial provides some additional insight into the process I’ve just described. NOTE: We feature several botched verifications in a number of Tech-News articles. |

|

||||||||||||||||||||||||||||||

|

Should a Verification or an Annual Inspection be carried out on a system that you know to be non-compliant (or that you know will "fail" even before you start)? Where should you "draw the line" (call it a day) and reschedule? Someone once said “there are no dumb questions, just obvious answers”. There are several things that should preclude a reasonable person (or in this case a trained professional) from even starting a Verification or an Annual Test. Obviously if there isn't any power to the panel (or it was displaying a "ground fault") you wouldn't (shouldn't) commence testing until the problem has been rectified. If the panel won't "reset" properly, or is completely unresponsive, testing should be curtailed. You should also not test devices that have been identified as non-compliant such as smoke detectors that aren't cross-listed to the control, or manual stations that do not have (or have never met) ULC Listing requirements. Examples of the latter would include pull stations that only bear a "CSA" mark or that use the round breakable disks which are often replaced with metal washers (Yes, I've actually seen this done!) by building owners because the disks are no longer available or are difficult to source. |

|

||||||||||||||||||||||||||||||

|

How can a local authority properly vet (authenticate) a verification report? There are several ways this can be accomplished:

|

|

||||||||||||||||||||||||||||||

|

Who has final authority to accept a fire alarm system installation? The answer to this question can be abbreviated into three simple initials: A H J (short for the "Authority Having Jurisdiction"). In Canada, on new installations, that is the Building Inspector, the Electrical Inspection Authority (or a combination of both). On renovation/upgrades, it's the municipal (or local) Fire Chief (usually in co-operation with the Electrical Inspector). All of these agencies however, rely on one individual's report and written comments before an occupancy permit can be issued. On new installations, not even the Design Engineer will sign off without this all important report. The onerous task of determining whether-or-not a fire alarm system (or a component added to it) meets all the installation and performance criteria is the trained professional technician performing the verification. This individual is the acknowledged expert upon which everything hinges. He is the one charged with ensuring that all aspects of the installation meet the code requirements, applicable standards, and the manufacturer's testing criteria. The verification technician's job is pretty cut and dried. There is no "gray area" in any of the codes or standards that reference a fire alarm system installation. As the verifying authority, it is extremely important for the technician to understand that. No AHJ will dispute your decision to reject an installation that doesn't conform to the standard regardless of whether an Engineer has "designed" it that way, or a municipal "plan checker" has accepted it. Hopefully you will have had an opportunity to discuss what you perceive are issues that may hinder your acceptance of the system well before the final nail is driven and the paint has dried. It is for this reason I have always advocated a verification agency gets involved at the start of a job (even as early as the plan acceptance process). Nobody likes "surprises" at the end of a job. Not only are they costly in terms of "correction", the delays they represent could wind up costing the contractor penalties and other associated costs. |

|

||||||||||||||||||||||||||||||

|

Which code references CAN/ULC-S537 (Standard for Verification of Fire Alarm Systems) thereby making it a legal document? First of all, the referenced standard (as well as the other applicable standards) represents the collaborative effort of several committed individuals that hail from a variety of backgrounds and disciplines. Some work for fire alarm manufacturers, engineering firms and local building inspection authorities. Most are volunteering their expertise and their time. CAN/ULC-S537 represents the minimum acceptable criteria for the testing and commissioning of a fire alarm system. In Canada, Provincial Building Codes primarily reference both CAN/ULC-S524 and CAN/ULC-S537 in their requirements for the installation of a fire alarm system (which also demonstrates how a "standard" becomes "accepted" or "legal"). In British Columbia, BCBC (2018) Section 3.2.4.5 is titled "Installation and Verification of Fire Alarm Systems". BCBC (2018) 3.2.4.5 (1) "Fire alarm systems including the voice communication capability where provided, shall be installed in conformance with CAN/ULC-S524, 'Installation of Fire Alarm Systems'." BCBC (2018) 3.2.4.5 (2) "Fire alarm systems shall be verified in conformance with CAN/ULC-S537, 'Verification of Fire Alarm Systems', to ensure they are operating satisfactorily." |

|

||||||||||||||||||||||||||||||

|

How many times is a fire alarm system verified (or how many times can a fire alarm system be verified)? A fire alarm verification inspection is normally conducted when a newly installed fire alarm system is commissioned. There are some additional provisions within CAN/ULC-S537 (Verification Standard for Fire Alarm Systems) and Provincial Fire Codes that will trigger the requirement for a verification or special audit however. These can include additions or modifications to an existing fire alarm system, replacement of components such as booster power supplies, the common control's motherboard, zone expansion modules, control circuits, annunciators, and initiating or indicating appliance modules. Replacement or repair of any system wiring will also trigger a verification but this is usually limited to the affected devices on that zone or circuit. On rare occasions an order by the Authority Having Jurisdiction may require the building owner to have the fire alarm system verified (a recent incident involving several grow-ops in an apartment building in Vancouver comes to mind). |

|

||||||||||||||||||||||||||||||

|

"I'm concerned with the attached fire alarm Verification Report. It doesn't remotely resemble another report we received on a similar project we manage in Burnaby. What should we do, and whom do we contact to give us the proper information?" Here's a portion of my response: This bogus Verification is featured in a Tech-News feature story. For a more recent one, you can review this article. What's the proper format for a verification report? Reference the Appendix in the Verification Standard - CAN/ULC-S537-04 (alternatively, you can go to our FORMS page). If the report in front of you doesn't comply with either of these suggestions, then the verification is DEFINITELY NOT VALID! |

|

||||||||||||||||||||||||||||||

|

What is a Fire Alarm Verification Certificate? This is a document provided by most fire alarm manufacturers following the commissioning/verification of a new fire alarm system. As it isn't specified or identified (hence not required) in any part of the Standard for the Verification of Fire Alarm Systems (CAN/ULC 537), it's not normally my practice to issue one. I must admit that some certificates I've seen are nice enough looking to be considered art (you could even have them professionally framed). The fact that it's mostly manufacturers that have adopted the use of certificates, some Engineers and Architects actually NEED one before they will sign off on their project (and that's just one of those times when you've gotta "go with the flow"). We can provide customized Certificate forms. Check out our LIBRARY for more information and pricing. |

|

||||||||||||||||||||||||||||||

|

What should a Fire Alarm Verification Test Report (CAN/ULC-S537 Appendix “C” or Section 28) include? The basic documentation that must be provided for any Fire Alarm Verification performed in Canada is outlined in the Standard for Verification of Fire Alarm Systems - CAN/ULC-S537. The “04” version is in effect in most Provincial Jurisdictions with the exception of Alberta, which has adopted the “13” version. Local authorities may require additional documentation or may require you to submit an amended Appendix "C" form, as the City of Vancouver has done in Bulletin 2000-021-EL for Verifications performed in their jurisdiction. Make no mistake, the changes they require on the “C1” first page of the report DOES NOT RELIEVE A VERIFIER FROM SUBMITTING THE MINIMAL DOCUMENTATION REQUIRED BY THE STANDARD! Our forms C1 page happen to be based on the Vancouver Bulletin (I am, after all, based in Vancouver) but include the signature lines for an assisting technician/contractor and the fire alarm designer. They are available in our FORMS section. One other thing you’ll notice is that the “04” Version is “amended” to more closely follow CAN/ULC-S537-13. To suggest that ANYONE engaged in the Life Safety Profession follow a Verification Standard that has no testing parameters for some of the changes introduced in CAN/ULC-S524-06 (the Standard for Installation of Fire Alarm Systems) is asking them to assume some potentially serious liability issues. CAN/ULC-S537-04 - Section 3 of the Standard for Verification of Fire Alarm Systems details what you MUST provide in the way of documentation. The Appendix “C” to this Standard represents the MINIMUM required documentation in accordance with referenced Section. This consists of the following: C1. FIRE ALARM SYSTEM VERIFICATION REPORT (Subsections A through K) CAN/ULC-S537-13 - Section 4 of this version of the Standard for Verification of Fire Alarm Systems has the following required Appendix items: C1. FIRE ALARM SYSTEM VERIFICATION REPORT (Subsections A through L) CAN/ULC 537:2019 - Section 28 is entitled Fire Alarm System Verification Report and must include the following sections (without exception): 28.1 FIRE ALARM SYSTEM VERIFICATION REPORT NOTE: NBC 2010 (now adopted in ALL Canadian jursidictions) Sentence 3.2.4.22(2) REQUIRES that fire alarm systems employing emergency voice communications MUST be able to achieve a minimum intelligibility level of 0.7 CIS. This was moved to the Appendix of the Building Code and is now a guide item. |

|

||||||||||||||||||||||||||||||

|

If I change a fire alarm device, do I need a verification? This question opens a huge can of worms. Section 7 of CAN/ULC-S537-13 details the minimal acceptable criteria (in Canada). Sentence 6.3 states: “Where a field device is replaced, the device shall be verified in accordance with this Standard.” See what I mean by a can of worms? Too onerous? Perhaps. Is it common practice? Not in my experience (in fact my original answer to this question was “no” because in the almost thirty years I've been working in this industry, no one I know has ever been required to and I’ve never seen it done). The Verification of a field device requires you to check the wiring meets all the manufacturer's requirements and that of CEC. In most instances a service technician (someone that's trained to perform annual testing) isn't familiar enough (or even qualified) to make that sort of judgement call, and more often than not, he's the one that’s going to be replacing the detector. You must check that the device is properly supervised. If you're changing a device and the panel doesn't indicate a “trouble” when you’ve disconnect the wiring, you have a problem. If you're changing a device and haven't checked that it's compatible with the system, you have a problem (I have been called in to service a number of systems where incompatible smoke detectors have somehow managed to "find" their way "in" over the years). If the back box isn't properly grounded or a test of the ground fault circuit yields negative results, you have a problem. If you can document that you have performed all of these tests, I believe you will have satisfied the intent of the sentence BUT it's extremely important for you to check with your local AHJ as to whether-or-not they will ask you to comply with the actual Standard. TIP: If you're changing out a device that utilizes a "plug-in" style base where you don't have to disconnect any wires, the requirement to document the associated tests (supervisory, ground fault, and operation) could be limited to a simple work order appended to the original verification report. Now, If you're "upgrading" a heat detector to a smoke detector, the answer will be a definite "yes". The answer's the same if you go the other way (changing a smoke to a heat). What you're doing in this instance is changing the parameters by which the system was originally designed. If you're working in Vancouver, it's best to make yourself familiar with Bulletin 2000-021-EL. |

|

||||||||||||||||||||||||||||||

|

What's the acceptable voltage drop between the fire alarm control panel and the end-of-line resistor? CAN/ULC 524:2019 Clause 7.6 states: “The voltage drop and power dissipation on any circuit shall not prevent the proper operation of that circuit and shall be in accordance with the manufacturer's installation instructions.” This can vary significantly between manufacturer, panel models, and modules. That's why it's really important for you to be able to reference the installation manual for the panel you're testing. You'll also be able to determine if the correct gauge of wire has been used for the estimated length of the run. |

|

||||||||||||||||||||||||||||||

|

When a manufacturer "recommends" using a certain kind of wire and the contractor decides to run something altogether different, how should a Verifier address this? In order to answer this question in the correct context, let's use a recent example I came across. The contractor elected to install an addressable fire alarm system in this large warehouse project in Richmond. The fire alarm installation instructions hadn't even been "cracked" when we arrived to terminate the telephone line to the newly commissioned fire alarm communicator, yet all the necessary wire had been run and the panel was essentially ready for final termination and start-up. The remote annunciator was located over 150 metres away and mounted external to the building. The contractor had pulled a single 18/5 fire cable and four 12 gauge wires from the fire alarm control to the annunciator location. He had also terminated all of the wiring into the bottom of the control panel's back-box (on my advice this last bit was, at least, corrected). When I showed him the relevant pages in the manual, he made a comment that the installation was as he was instructed to do. I didn't argue with him, but explained that he might have some problems when it came time for the Verification. This is where it get interesting. If you look at the installation manual from the manufacturer, it states quite plainly that you must employ "twisted shielded pair" for the RS-485 communication loop between the panel and the remote annunciator. It also clearly illustrates that separate cables must be used for annunciator power and communication. The manual for the annunciator, however, states that it is "recommended" that twisted shielded pair be used. While some could interpret this as to mean that twisted shielded pair isn't "required", I hold with the premise that the installation manual for the panel takes precedence in this case. The Verifier MUST ensure that the wire type and gauge meets the requirements of the manufacturer (CAN/ULC-S537-04 Section 3.3.3.1). But, can you still use 18/5 fire alarm cable for both power and communication for a remote annunciator? NO!! The project employs motorized bells on two separate bell circuits also wired as Class "A" utilizing 18/5 fire cable (this is in itself a "no-no" as a typical Class "A" installation requires a physical separation between the "primary" and "alternate" (or return) runs in accordance with both the “01” and “06” versions of CAN/ULC-S524). The manufacturer provides a table in the manual that presents the information necessary for the contractor to determine the correct gauge of wire for the anticipated current draw on the circuit in an easy to read format. Utilizing the correctly sized wire is crucial to remaining within the 1.8 volt maximum allowable drop between the panel and the last device on the circuit. Since, in this example, this has been wired as a Class "A" loop, the "last device" is that device on the "return side" just before the final run to the panel (I normally perform my voltage drop measurement from inside the panel when the last device is within thirty feet). The length of the two signal circuit runs in this building (and the anticipated current draw) requires the use of a heavier gauge wire and I would be surprised if the voltage drops on the signal circuits are within the specified parameters. If it's not? This must be flagged as a deficiency by the Verifier and corrected! TIP: Anyone engaged the sale of fire alarm system components in a contractor's local area should be ready to assist their customer with advice and instructive comments to ensure the Verification of the installed components goes off without a hitch. Furthermore, as a Verifier, you cannot "overlook" such obvious deficiencies as a favour to your customer. Such an obvious divergence from the applicable Standards (even if it's "well intentioned") will eventually come back to "bite you" |

|

||||||||||||||||||||||||||||||

|

Alberta requires that the Design Engineer be involved in the fire alarm Verification. Does this not conflict with the requirements of the Standard for Verification of Fire Alarm Systems (CAN/ULC-S537-13 and CAN/ULC 537:2019)? Another good question! Most definitely the provision in Alberta's STANDATA represents what appears on the surface to be a radical departure from the intent of the Verification Standard. Alberta remains the ONLY Provincial jurisdiction that actually requires the Design Engineer to participate in the Verification process. However, if you examine the intent of the specific Code requirement, you will also notice that the Engineer's role forms part of the final acceptance of the system and that a "third party" Verifier is still involved. To my way of thinking this is no different than an electrical contractor providing personnel to assist in the Verification. The fact that the Verification documents that are finally submitted also include the Engineer's seal is, in my opinion, simply another safeguard designed to ensure the system fully complies with the Installation and Verification Standards, the Canadian Electrical Code, and the Building Code. Is Alberta's "system" any more fool proof than what's in place in other Provincial jurisdictions? The onus to ensure the equipment is installed in accordance with all of the aforementioned requirements falls on the independent Verifier, and that dear Reader, still has the potential to lead to a "royal cock-up". |

|

||||||||||||||||||||||||||||||

|

What do you do when you discover a non-compliant system that was installed only recently and verified by the manufacturer (or an individual that was approved by the local authority)? You must notify the local electrical authority and the Fire Department's Fire Prevention Office. Here are examples of some of the installation deviations we've come across recently (keep in mind that in each instance a Verification was conducted by an individual "approved" by the local authority):

|

|

||||||||||||||||||||||||||||||

|

Can a technician who is going to perform a fire alarm verification terminate wiring (or be involved in assembling components) in the system’s common control? Note: Much of this FAQ was the subject of a Tech-News & Views story we featured in April 2012. The wording is identical. A Verifier should not be getting involved in the installation or design of a fire alarm system. The rule was articulated in the Preface to the actual Verification Standard (CAN/ULC-S537-04) and stated: “The requirements of this Standard contemplates that the verification procedure described herein will be conducted by an organization other than the installing contractor and designer, and that the verification will be carried out by qualified personnel in the employ of an organization acceptable to the authority having jurisdiction. Refer to Appendix A, Qualified Personnel.” Appendix A stated: “A1 Any person who performs the verification of a fire alarm system should be familiar with this Standard and have received suitable formal training or sufficient experience acceptable to the authority having jurisdiction.” The Standard doesn’t mention anything about the person programming an addressable system not being involved in (or performing) the Verification, yet this has become the accepted “norm”, just as many jurisdictional authorities will accept, without question, the Verification of a technician in the employ of the fire alarm manufacturer (or their designated agent). Factory (manufacturer) training does NOT necessarily qualify an individual to perform a Verification, but when push comes to shove, who are you going to call? It’s also interesting to note that, with very few exceptions, many of the more complex panels these days require a great deal of design (power supply calculations, module layout, bin sizing, and final terminations) which, most often are performed by these same technicians (an Engineer at the factory may also be frequently involved). How can this be so (when you consider the wording suggested by a previous edition of the Standard)? Simple. Most electrical contractors tend to shy away from the responsibility of performing these particular tasks because many addressable controls which employ multiple module racks also have very complex interconnections which only a factory trained technician would recognize and be comfortable working with. Then there’s the issue of the manufacturer’s warranty. It’s difficult to return a component that’s obviously been connected incorrectly. Blackened boards and burned components make for very poor warranty claims and an electrician who isn’t familiar with the product definitely shouldn’t be working anywhere near the common control. There are many types of controllers these days that are normally terminated by factory trained specialists. Heat trace, lighting, telephone, access control, HVAC, fire pumps, generators, and security are all good examples. I think it behoves the responsible, manufacturer trained professional to perform final terminations on the control panel for any critical building system (a life safety system represents, without question, the most important of those I mentioned in the previous paragraph). Adopting such a practice will also, in my opinion, go a long way towards mitigating many of the errors I continue to document on this site. It is absolutely crucial to understand that I am not advocating a technician get involved with running wire, the physical installation of the head-end equipment (control panel and/or transponder) or field devices (that must still be left to the electrical contractor so as to ensure that the requirements mandated in the Standard aren’t compromised). |

|

||||||||||||||||||||||||||||||

|

How many turns of a sprinkler isolation valve are required before a supervisory condition has to be annunciated at the fire alarm control panel? The newest edition of the Standard (2019) the “audible common trouble signal” is a latching supervisory signal. The requirement in the Standard is articulated in Clause 21.2.1: “Each shut-off valve position supervisory switch shall be tested to determine that within two turns of the valve handle, or when the stem of the valve has moved 20% from its normal position, it shall result in an audible common supervisory signal and a visual indication.” Most AHJ’s will insist the Building Code requirements be followed in this respect regardless. NBCC 2020, Sentence 3.2.4.9.2 states: “An automatic sprinkler system shall be electrically supervised to indicate a supervisory signal on the building fire alarm system annunciator for each of the following: (a) movement of a valve handle that controls the supply of water to sprinklers; ...” NOTE: Many older type fire alarm panels may not be capable of providing a latching supervisory signal, but will, instead, indicate a common trouble. In this instance, you should note they type of signal that is indicated on the report form. If the zone is shared between the isolation valve and the alarm switch, you must ensure that the alarm overrides the trouble condition. To do this, close the valve enough to annunciate the trouble and then perform your alarm test. |

|

||||||||||||||||||||||||||||||

|

The service technician just replaced the main CPU module on my fire alarm control panel. Part of the procedure required him to upload software. Is a Verification required? Most definitely YES! The relevant section of the Standard is entitled 7. System Modifications and specifically 7.10 and 7.11 (these Clauses have all been moved to Section 27 of CAN/ULC 537:2019): “7.10 Modifications to a control unit or transponder and those circuits affected shall require the modifications to be verified in accordance with Subsection 4, Verification Procedure - Control Units and Transponders.” “7.11 Software modifications shall be tested by one of the following methods: A Reverifying all system functions that could be affected by the modifications with the exception of wiring supervision; or B A comparison of the ‘before’ and ‘after’ software utilizing mediums such as a printout or compare program.” With respect to 7.11B, on a NEW CPU, there would be NO “before software” to compare the system functions with (as the new CPU would have no prior data in it). In this instance it would trigger the requirements of Section 7.11A. |

|

||||||||||||||||||||||||||||||

|

Why is it important for the fire alarm verification agency to be present when the final inspection is being done on a smoke control/smoke management system? A smoke control/smoke management system is a crucial component of a buildings life safety system design and will often be triggered by a fire alarm system. The fire alarm control may also include functions for stairwell pressurization fans, exhaust fans, elevator recall, make-up air fans, etc. No one would be more qualified to identify and operate the fire alarm control to ensure a successful and efficient test experience. In most cases, the Verifier may also have been involved in programming addressable components integral to operation of the smoke control system and would be in a position to make any changes the testing may identify as necessary to meet the design criteria. The National Building Code now requires all of the Building’s Life Safety Equipment and Standards to be “Commissioned” as part of an integrated system. The Standard that’s referenced in this instance is CAN/ULC-S1001-11. |

|

||||||||||||||||||||||||||||||

|

What is a fire alarm Verification sticker, and is one required to be installed/affixed to a control unit? This is usually a label which identifies that the fire alarm system has been Verified to CAN/ULC-S537. It will usually include a date, company identification, and a technician’s signature. Application of a sticker (or similar label) may be a somewhat helpful indication that the system was tested, but it is not a requirement of the Standard. What the Standard DOES require is for the technician conducting the Verification to provide a copy of the Appendix “C” (Section 28) Report to the owner (or owner’s representative) and for it to be readily available for review on the premises or at the fire alarm panel. The Appendix “C” (Section 28) Report must remain in place for the life of the fire alarm system. A sticker tells you nothing about what has been tested, and usually does not identify deficiencies that may be present in the system. Sometimes, the sticker is often covered over, removed, or defaced (often by a rival service agency). It is extremely important that the AHJ (or other building official) has access to a physical copy of the completed report. It will assist the technician performing the annual service of the system to identify the locations of the connected field devices (such as end-of-line plates, duct detectors, remote relays, etc.) This having been said, please check with your local jurisdictional authority to see if they require you to provide a service sticker (or label) referencing the specific Appendix “C” (Section 28) Report on the control unit or annunciator. |

|

||||||||||||||||||||||||||||||

|

I will be replacing the CPU, all modules, power supply and batteries inside fire alarm panel due to water damage. This is a 12 story building, with 150 units. When conducting the Verification, do all devices in the suites and common areas require testing, or can I test one device per circuit, per floor? Your job falls under Section 7 of CAN/ULC-S537-13 Standard for Verification of Fire Alarm Systems (Section 27 of the 2019 Version). Clause 7.8 states: "Where an existing fire alarm system control unit or transponder is replaced with a new control unit or transponder, it shall be verified in accordance with Subsection 4, Control Units and Transponders, and any existing devices shall be tested in accordance with Section 5.7 (Field Devices) of CAN/ULC-S536, Standard for Inspection and Testing of Fire Alarm Systems. (Refer also to Clause 7.11)" Clause 7.11 states: "Software modifications shall be tested by one of the following methods: I’ve included Clause 7.11 even though your question is answered by Clause 7.8 because of the specific reference to it. NOTE: You will have to drop the end-of-line plates. You must document the voltage readings at each one on the remarks line of the Individual Device Test Record (this is a required test item in both CAN/ULC-S537-13 and CAN/ULC 537:2019). This will ensure that the wiring hasn't been adversely affected between the common control and the last device in the circuit which may exceed the allowable voltage drop stipulated by the manufacturer. |

|

||||||||||||||||||||||||||||||

|

Where can I download a Fire Alarm Verification Certificate? As we mentioned in this FAQ, there is no requirement in CAN/ULC 537 for a Verification Agency to provide such a certificate, however, some jurisdictional authorities are used to seeing them (and you’ll often find engineers want them as well). We do have a number of examples available that can be customized to order (at a nominal cost). Please visit our LIBRARY for more information. |

|

||||||||||||||||||||||||||||||

|

CAN/ULC-S537-13 is the Verification Standard specified in NBC 2015. CAN/ULC-S524-14 is the Fire Alarm Installation Standard specified in the same Code. How does a Verifier resolve the conflict between the two different versions of Table 2 (System Response Times)? In order to Verify compliance with the Installation Standard in effect, it is incumbent upon the professional conducting the fire alarm Verification to ensure that all testing appropriate to the fire alarm installation is being conducted. The fire alarm Verification documentation must reflect this required testing and appropriately amended. The true mark of a professional Verifier is his/her ability to utilize the knowledge gained through careful and thoughtful consideration of the relevant Codes, Bylaws, and Standards as they apply to the jurisdiction in which they practice. You have access to the most comprehensive testing forms available from our FORMS page. The adoption of the 2020 National Building Code will require Fire Alarm Verifications be performed to our newest Standard, CAN/ULC 537:2019. There are significant changes to this Standard, starting with the fact that we’ve moved the report form out of the Appendix to the NORMATIVE part of the Standard. It’s no longer going to be an “Appendix C Report”. It’s now called a “Section 28 Report”. |

|

||||||||||||||||||||||||||||||

|

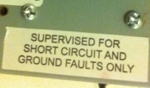

How do you Verify the installation of fire alarm isolator modules? Excellent question! The testing methods vary slightly depending upon the type of isolator (as well as who manufactured it). It’s a good idea to have the installation instructions handy for the model of isolator you’re testing. This will usually include a recommended test procedure that might differ slightly from what you read here. There is additional information regarding installation methods for the various isolator types located in this Special Report! NOTE: The manufacturer’s sugggested test methods should be used in EVERY case. First of all, you have to recognize that there are now THREE types of isolator modules available for use in a fire alarm system. Let’s look at each one and examine the suggested testing methods: SLC (Signalling Line Circuit) or DCL (Data Communication Line) Isolators: These units ensure survival of the two wire communications loop which serves addressable (sometimes referred to as “analogue”) fire alarm field devices (smoke detectors, pull stations, heat detectors, etc.). Many of the more popular isolators out there are what’s termed “dumb” devices (in other words, they don’t have much in the way of internal “smarts”). They’re essentially a relay module that’s designed to isolate a short on the data circuit within a certain area or that may affect a number of devices assigned to the isolator. Regardless of what method they employ to identify a fault on the data loop, their main function is to isolate that fault to a few devices while ensuring the overall integrity of the system isn’t compromised. Testing method - There are two termination points on every isolator. One is an “in” from the common data loop and the other is an “out” to the field devices it serves. Short the “out” side to ensure the unit functions correctly (yes, this means that you will have to remove the cover on each unit!). Depending on the number of devices on the “out” side, you should see a string of error messages on the common control that are most commonly identified by the phrases “missing device” or “device error”, or “data loop short”. Maintain the short until you have scrolled through and noted each device that fails to report. Part of your “test” ensures that the total number of devices for each isolator does not exceed the manufacturer’s maximum limit. If more than one floor area’s devices fail to report while the short is in place you will have to note this as a deficiency on your report! If the isolator you’re testing happens to be bi-directional proceed to short the “in” side. Maintain the short until your helper has scrolled through and noted each device that fails to report. Field devices which employ isolator bases must also be tested. If the system you’re testing employs these units (it’s usually the first smoke detector on the loop), you’ll have to find an addressable device (a manual station is usually the easiest to access) downstream of the isolator. Drop it and short the loop terminals from here. Maintain the short and have your helper scroll through and note each device that fails to report. Power Supply Isolators: These units ensure that the common power supply buss is not compromised by a short on one (or a series) of the field devices it serves. These are fairly uncommon on systems installed to date, but where they are used, an appropriate test must be conducted to ensure their operation. Testing method - While shorting a power supply is not normally recommended, opening the circuit on the “out” side of the isolator will identify the devices it protects. You must ensure the maximum current for the unit is not exceeded (or the recommended maximum number of devices). Use your meter (set to “amps”) to determine what each isolator is handling. In EVERY case, follow the manufacturer’s suggested test methods and note the results in your report. Notification (Bell/Buzzer Circuit) Isolators: In British Columbia (and most jurisdictions across Canada), the NBC mandates that insuite sounder devices must be installed on a separate signalling circuit from the common area notification appliances. For more detailed information, please read our FAQ which details the Code requirements. There are two physical tests which must be performed at each isolator. They are the supervisory test and the operation test. The Standard for Installation of Fire Alarm Systems requires that these units are installed in the common area corridor outside of the suites they serve. They’re always located behind a suitable cover which identifies them as a fire signalling component or fire alarm device. There are two “flavours” available: “supervised” and “unsupervised”, The unsupervised isolator is NOT allowed by Code or the installation standard (CAN/ULC-S524). If you come across one (they will have a label affixed to them identifying them as such), you must fail the unit. No further testing is required. This is a label on an Caution! Use of ANY unsupervised Testing method (CAN/ULC-S537-13) - There are two phases to the required testing. One is performed while the system is in normal supervisory mode, the other is performed while the system’s sounders are active. It is recommended that most of the testing involving the actual operational component of the isolator be performed inside the suite the unit serves. You will notice that there are two “outputs” on each isolator (it serves two separate suites or units). All in-suite devices controlled by an isolator are wired in a Class “A” loop. Step 1 - Remove the cover from the isolator to expose the wiring terminals. Testing method (CAN/ULC 537:2019) - The supervisory short test outlined in Step 8 and Step 9 has been removed from the Standard. Take off the short imposed in Step 7, have your helper initiate a fire drill test and proceed to Step 10. If all of the above tests are completed satisfactorily, you can move on to the next suite on the floor (after reinstalling the buzzer that is!). NOTE: If, in step 8, none of the buzzers in the suites sound, then the notification appliance circuit is programmed incorrectly! You must ensure this is corrected before proceeding with the testing of the rest of the insuite appliances. Some systems utilize a jumper setting to activate the signals if isolators are on the circuit. Other systems require access to the physical panel programming to enable this feature. |

|

||||||||||||||||||||||||||||||

|

|

|

||||||||||||||||||||||||||||||

The Fire Technicians Network

+1 (888) 340-3473

“We are not a professional union, but together, we are a union of professionals!”

What we’re all about!

We are not affiliated with ASTTBC, CFAA, CANASA, NFPA, NAFED, or NICET (although we encourage you to explore and objectively evaluate the benefits associated with supporting their individual efforts). Membership in the Fire Technicians Network is entirely voluntary. Are you up to the challenge of demonstrating your commitment to public safety and the highest standard of professional practice?

Copyright © 2007 - 2023 The Fire Technicians Network. All Rights Reserved