TECH Q & A (FAQ’s)

|

|||||||||||||||||||||||||||||||||||||||||

|

“We live in a society exquisitely dependent on science and technology, in which hardly anyone knows anything about science and technology.” IMPORTANT: 2019 PUBLISHED EDITION OF CAN/ULC 524 We’ve updated this page to reflect the introduction of our latest Canadian Standard for Installation of Fire Alarm Systems (CAN/ULC 524:2019). ULC’s new numbering system also eliminates the “-S” (as in CAN/ULC-S524-14) and incorporates the full YEAR reference the Standard was first published. ULC Standards are now undergoing continuous review and, where changes have been incorporated, you will see a reference similar to this: CAN/ULC-S1001-11-REV2 or CAN/ULC 561:2022-REV1 Unless specifically referenced in a provincially (or territorially) adopted Building or Fire Code, a revised Standard won’t normally apply. You should check with your local Building or Fire Official to ensure your installation complies with any applicable Bylaws or Bulletins which may call a specific REVISION into effect. The City of Vancouver’s website has recently undergone a major upgrade. Many links to Bulletins from our website will, as a result, now display a custom error page. If you happen to come across this, simply type former. (the dot is important) ahead of vancouver in your browser’s address bar, and it should open the proper document. We’ll endeavour to update all of our links once the COV Web-Minions get finished fixing theirs! As you navigate through the various FAQ pages on our site, you’ll notice that we’ve provided handy pointers that highlight information which might be of special interest in the answers we’ve provided. Look for these symbols in the right hand margin:

|

|

||||||||||||||||||||||||||||||||||||||||

|

FIRE ALARM INSTALLATION: How many bells can you connect to a Class “B” signalling circuit? In Canada, are there fire alarm systems or devices that use purple wires? Can a class “A” circuit employ “T”-taps? What’s the maximum distance allowed between a tamper switch & an addressable monitor module? How many speakers can you install (wire up) on a speaker circuit? Can wiring for a fire alarm system be run through the same hole cored for fire sprinkler pipe? |

|||||||||||||||||||||||||||||||||||||||||

|

How high should an end-of-line resistor be mounted? Is wiring to an annunciator panel required to be fire rated? Can I install a heat detector by myself? How far from a wall does a fire alarm isolator need to be? Can you mix Class “A” with Class “B” circuits on a fire alarm system? Can a Class “B” wired fire alarm system support horns? Do relays for a fire alarm system need to be ULC Listed for fire alarm application? Can an Engineer approve the reduction of the number of required heat detectors in a given area? What’s the correct end-of-line resistor to use with a System Sensor C2W-BA smoke detector? How many fire alarm bells are there in a typical elevator hoist way? How do you terminate shielded cable in a manual pull station (or other field device)? What’s the difference in price between a proprietary and non-proprietary fire alarm system? Where can I find the testing form for the Canadian Fire Alarm Installation Standard (CAN/ULC-S524)? Can you run power and DCL (SLC) wires together in the same conduit (raceway)? Where shielded pair cable has been specified, can I use BX (flexible armour sheathed) cable? Why must proper polarity be observed when installing signal devices for a fire alarm system? What is the maximum wire length you can run to and from a smoke detector in the same conduit? Can green wire be used to connect fire alarm circuits? In Canada, is a ground wire required on a fire alarm system in which rigid EMT (conduit) is used? Can I use UL Listed wire on a Canadian fire alarm installation? Does an isolation module go before or after the next floor? How many flow switches can be put on one fire alarm panel zone? Does every device connected to a fire alarm system in Canada have to be ULC Listed? Can a fire alarm system annunciator be installed outside on an exterior wall (in Canada)? What testing should be done before field wiring connections are terminated in a fire alarm panel? How many devices can be "T" tapped on a fire alarm system? What's the maximum allowable mounting height for a fire alarm control panel? Are you allowed to run fire alarm input and output circuits in same conduit (or wire raceway)? How do you properly connect two fire alarm panels together? Can end-of-line resistors (for multiple circuits in a room or area) be mounted in one box? How do you tie in (interconnect) door holders on a fire alarm system? How many sprinkler tampers can you legally hook up to a single fire alarm supervisory zone? Can you review the relevant codes regarding the installation of in-suite signaling appliances? Can security wires be run with fire alarm wires in Canada? Does the fire alarm circuit disconnecting means have to be painted "red" and locked "on"? How many initiating devices can you have on a fire alarm system? Are there any fire alarm relays listed for tripping from a notification circuit? What's the Code say about monitoring sprinkler valves? Where should a fire alarm control panel be installed? How do you add an isolator module to an existing fire alarm panel? Is it permissible to have different audible signal devices in the same building? What is the maximum mounting height for a fire alarm pull station in Vancouver? Can fire alarm wiring be painted? Do you require a class "A" circuit for a fire alarm emergency communications riser? What is the allowable distance between power and non-power (limited) cables? Where does it state that you can’t install fire alarm devices until the walls are painted? |

|||||||||||||||||||||||||||||||||||||||||

|

FIRE ALARM SYSTEM UPGRADES AND RETRO-FITS: |

|||||||||||||||||||||||||||||||||||||||||

|

|

|

||||||||||||||||||||||||||||||||||||||||

|

Can you run power and DCL (SLC) wires together in the same conduit (raceway)? If by "power" you mean 120VAC, most definitly NOT! Otherwise, the same provisions as outlined in this FAQ would apply. |

|

||||||||||||||||||||||||||||||||||||||||

|

Where shielded pair cable has been specified, can I use BX (flexible armour sheathed) cable? BX or other styles of armoured cable is not a substitute for actual shielded wire. When a manufacturer calls for its use, you are required to provide it. There are no suitable substitutions allowed (at least in Canada). In most cases the shield must be kept separate from the building's electrical ground, and also remain continuous from the fire alarm panel to the device being connected. The armoured sheath of a BX type cable is, with very few exceptions, grounded whenever it's terminated to a junction or outlet box (at least it should be!). |

|

||||||||||||||||||||||||||||||||||||||||

|

Why must proper polarity be observed when installing signal devices for a fire alarm system? A Notification Appliance Circuit (NAC) or Indicating Circuit is rather unique. It must provide supervision of the devices in the circuit and be able to switch "on" to activate the bells, horns, and strobes that are part of it. To accomplish this, a diode is utilized in each device which will only allow current to flow in one direction. Thus, in supervisory mode, the fire alarm panel will "see" the end-of-line device as a "normal" condition on the NAC but the current required to perform this function won't activate the sounder as the diode will prevent the current from flowing through it. When the fire alarm control goes into alarm, the NAC current is reversed and the sounder or strobe-light is activated. It is common practice to label the NAC and individual notification device terminals in an alarm condition on a fire alarm control. In other words, the positive terminal of the indicating circuit will correlate with the red wire (or positive terminal) of the signaling device (to avoid confusing the guy installing it). Your voltmeter will, however, indicate the reverse when the control panel is in "normal" supervisory mode. |

|

||||||||||||||||||||||||||||||||||||||||

|

What is the maximum wire length you can run to and from a smoke detector in the same conduit? On a Class "B" loop you're pretty well restricted to the recommended wire length for the gauge you're using stipulated in a handy wiring table most manufacturer's provide in their installation instructions. Keep in mind that the table they provide is based on the minimum gauge used in the run (even if what you're pulling is heavier). On a Class "A" loop, the rules are a bit more restrictive. Figure 6.4 in CAN/ULC 524:2019 illustrates how to install both the primary and alternate wiring for a smoke detector in the same conduit as long as the room the detector(s) are located in is less than 100 square meters in size. There are a couple of additional exceptions to the rule all of which are illustrated in the Figures 6.2 and 6.3, respectively. Clause 6.1.3 details the requirements for wiring installation in a Class A configuration. |

|

||||||||||||||||||||||||||||||||||||||||

|

Can green wire be used to connect fire alarm circuits? Yes. You must adhere to the manufacturer's suggested wire type and gauge. No one cares if it's purple, pink, puce, or that pukey green colour that used to adorne the sides of the old Edwards vans. Green wire is normally associated with "ground wire" though. Personally, I would tend to avoid using it for that reason (it's too easy to get confused in some of the smaller enclosures). |

|

||||||||||||||||||||||||||||||||||||||||

|

In Canada, is a ground wire required on a fire alarm system in which rigid EMT (conduit) is used? Every fire alarm device back box must be individually bonded to ground. Fire alarm cable sold in Canada always has an odd number of conductors in the jacket (i.e. 3, 5, 7, 9, etc.). The requirements for bonding non-current carrying metal parts of electrical equipment is called up in Canadian Electrical Code Section 32-104 and stipulates such bonding must be provided in accordance with Section 10. Rigid metallic conduit (includes EMT or flexible) can be used as the bonding means, but Section 10 also proscribes that “electrical continuity of service equipment shall be assured” and that only copper can be used as the grounding conductor in a “wiring system” (Rule 10-802). NOTE: If, during the course of a Verification, you come across a situation where no bonding means has been provided, you must note this as an installation deficiency! |

|

||||||||||||||||||||||||||||||||||||||||

|

Can I use UL Listed wire on a Canadian fire alarm installation? You can use UL Listed wire as long as it's also CSA Listed. One word of caution, however. UL Listed fire alarm cable typically does not have a ground wire (you can't order it in "18/3", "18/5", "18/7", etc.). |

|

||||||||||||||||||||||||||||||||||||||||

|

Does an isolation module go before or after the next floor? CAN/ULC 524:2019 states in clause 48.1: “Where provided to meet the requirements of 18.1, fault isolators shall be utilized when entering and leaving each National Building Code of Canada required fire alarm zone. See also Annex A (informative) Explanatory Materieals, A.18, Circuit Fault Tolerance.” (actual answer underlined for emphasis) So the answer is quite clear. It’s installed as the FIRST device entering a floor area and as the LAST device leaving a floor area. There are a number of different configurations for the various wiring styles as well. These are outlined in the instructions accompanying the module (or in the fire alarm controls installation manual). You can also read more on installation and testing requirements for fault isolation modules in our Special Report. |

|

||||||||||||||||||||||||||||||||||||||||

|

Is it permissible to use a "normally closed" switch to monitor a "trouble" or "supervisory" condition on a fire alarm system? Certainly. Many devices use a normally closed switch: cover tampers on listed sprinkler flow and pressure switches, damper position indicating switches, and valve tamper cords (in some sprinkler rooms) to name a few. In every case, however, the circuit is supervised by an end-of-line resistor which has some very specific installation requirements. Some older fire alarm panels, for instance, are incapable of providing a latching supervisory signal which you will have to document if any changes or additions are made. |

|

||||||||||||||||||||||||||||||||||||||||

|

Does every device connected to a fire alarm system in Canada have to be ULC Listed? No. Not everything connected downstream of a fire alarm control (and which is part of a DESIGNED fire alarm system) must be ULC Listed. Many things connected to the relay outputs (often referred to as the “contractor terminals”) don't have to be either listed or supervised. In many instances fire alarm systems are also monitoring (and controlling) things like fans (for stairwell pressurization or parkade exhaust), dampers, and sprinkler heat trace controllers (to name a few). The switches and relays that provide these (and other) specialized functions are often NOT ULC Listed (in Canada they are usually required to be CSA Listed though). Fire alarm DEVICES however (such as smoke detectors, heat detectors, manual stations, horns, bells, etc.) MUST be ULC Listed in Canada (UL in the US). |

|

||||||||||||||||||||||||||||||||||||||||

|

Can a fire alarm system annunciator be installed outside on an exterior wall (in Canada)? Most definitely! A number of manufacturers provide ULC Listed weather-proof heated enclosures for use in outside environments. Always exercise the appropriate cautions (and some common sense) if you're faced with the requirement to do so. Keep in mind that the annunciator has to be visible (and readable) to the responding authority. I've seen many instances where they have been mounted on a south facing wall and daylight (and sunlight) conditions make them extremely difficult to read. What often happens is that exposure to the sun's U/V rays tends to fade labels at an accelerated rate as well. It is for this reason that you would want to ensure that the unit is sheltered from the elements as much as possible. Covered walk-ways or cupolas with lots of shade make ideal applications. Where you have extremes in temperature, it might also be wise to supervise the output of the power supply for the annunciator heater. Most often this is a 24VAC transformer. Keep in mind that the installation Standard (CAN/ULC 524:2019) requires that listed fire alarm control units and annunciators be maintained in a very specific temperature range (10 - 25 degrees C). This is articulated in Clause 12.7: “Except as permitted by 12.8, control units and transponders shall be located in an area with an average ambient temperature range between 10 degrees C to 25 degrees C and where the relative humidity does not exceed 90%.” |

|

||||||||||||||||||||||||||||||||||||||||

|

What testing should be done before field wiring is terminated in a fire alarm panel? Excellent question! The answer doesn't depend on whether you're terminating field wiring to a new installation or adding to an existing fire alarm system either, and furthermore, I figure that if you have to ask this question, you're not as familiar with the process as you should be and had better remain under expert supervision until you're confident enough with the process to fly on your own. Keep in mind that what I'm about to relate is very general in scope (the manufacturer may have some additional procedures you must employ before you put juice to the panel). The most important test is the one that ensures the fire alarm system is NORMAL in all respects. On a new system (particularly an un-programmed addressable one), this may prove to be somewhat challenging to the uninitiated. You should be familiar enough with the common control display to tell whether the system has booted normally. If you've placed end-of-line resistors across the NAC circuits, you should wind up with a local configuration error caused by un-programmed devices and attached expansion boards. Once the latter have been enrolled in the system, you should have as close to a normal display as you can get without having programmed any addressable field devices. Conventional Panels: On a conventional panel, I would suggest leaving the end of line resistors in place across both the input and output zones (in other words, don’t terminate any field wiring just yet). Before you power up, you should ensure you've configured everything for operation with all the appropriate jumpers installed (or removed) and any mechanical dip switches set. There may be some additional minor settings that require adjustment or programming, but once the system has been stabilized in the normal condition, you should have a green "AC ON" lamp illuminated along with any appropriate LCD/LED "system normal" display. Try shorting a few initiating zones and observing the responses of the panel. The appropriate alarm, supervisory or trouble relays should change state and the panel status should also change accordingly. Removing an end-of-line resistor should provide a "trouble" response. Grounding one side of any initiating or notification circuit should give you a "ground fault" trouble. Once you have determined that the panel is functioning normally in all respects, you can move on to terminating your field wiring. Before you do however, you should make sure that you're reading the appropriate end-of-line resistance on each incoming wiring pair. You should also check for anything unusual on the field wiring (such as voltage where there shouldn't be). More than one electrical apprentice has accidentally terminated an AC power circuit into a common control (in addition to the one required for the system's operation). You don't want to connect 110VAC to an input or NAC circuit! While you're checking the field wiring for resistance, you can also check for grounds on each circuit. Once you've determined that all is clear, you can start connecting each incoming wire to the appropriate zone terminals. Do this with the panel "hot" so you can pick up on any irregularities right away (devices with reversed polarities, for instance). This last bit also serves to remind me that I should mention that you should ensure any attached field devices have been properly terminated (nothing is more bothersome than to have one device on a circuit with reversed polarity). Addressable Systems: The "DCL" (or "SLC") loop wiring interconnects all of the addressable field devices on the system. The main difference between these types of systems and the conventional wired panel is that end-of-line devices aren't commonly seen (except on actual input modules or home-run NAC circuits). You should still check for shorts across the loops, however. You should test any NAC circuits the same way I've outlined for conventional panels. Also make sure you don't have any grounded wires and, on SLC loop wiring that employs a shield, make sure there's no continuity between the shield drain wire and the system ground or loop wiring. A quick way to test the integrity of the shield in the whole system is to short the shield wire at the last device in the circuit to one of the loop wires and then test for continuity (use the common loop wire because it's normally a "straight through" connection). If your meter reads "open", your shield is not continuous. |

|

||||||||||||||||||||||||||||||||||||||||

|

How many devices can be "T" tapped on a fire alarm system? First of all, a "T" tap is a type of connection in which more than two wires are joined at the same terminal (or wire nut). A "T" tap is essentially a "parallel" type of connection and that means that this question actually has two answers. On a conventional system - NONE. On an addressable system - Check the manufacturer's installation instructions. Many will limit the number of "T" taps allowed on a single circuit and may impose additional constraints as well. When in doubt, “RTFM” (Read the Freakin' Manual)! |

|

||||||||||||||||||||||||||||||||||||||||

|

What's the maximum allowable mounting height for a fire alarm control panel? For the answer to this question, we'll have to refer to two (2) published editions of the same ULC Installation Standard (CAN/ULC-S524), "2014” (which includes Amendment 1) and "2019" (even though they both say essentially the same thing). Most Provincial Building Codes are in the process of adopting NBCC 2020 (which references the 2019 published edition of the Standard). The 2015 National Building Coded references the 2014 published edition. Clause 5.1.4 states: “The top of control units or transponders shall be not more than 2400 mm above the finished floor level.” Clause 5.1.5 reads: “Visual displays and operating controls shall be installed in accordance with Clauses 5.2.3, 5.2.4, 5.2.5 and 5.2.9” and Sentence 5.2.5 adds: “The visual displays and operating controls of the annunciator or display and control centre shall be not less than 600 mm and not more than 1800 mm above the finished floor level.” In the 2019 published edition of CAN/ULC 524, Clause 12.4: “The top of control units or transponders shall be not more than 2400 mm above the finished floor level.” Clause 12.5 reads: “Visual displays and operating controls shall be installed in accordance with the applicable requirements of 13, Annunciators and Display and Control Centre.” |

|

||||||||||||||||||||||||||||||||||||||||

|

Are you allowed to run fire alarm input and output circuits in same conduit (or wire raceway)? Yes. With a few provisos (outlined in Section 4.4 of the 2019 published edition of the Installation Standard, the salient points of which follow). They must be of a similar voltage and meet the requirement of Sentence 7.5 of CAN/ULC 524:2019 (Clause 4.4.4 of CAN/ULC-S524-14): “Where wires for multiple circuits are installed in the same raceway or wiring compartment, the induced voltage or current of one circuit shall not adversely affect the operation of another circuit.” In some instances, the manufacturers also restrict you from running initiation and signaling circuits in the same cable assembly. |

|

||||||||||||||||||||||||||||||||||||||||

|

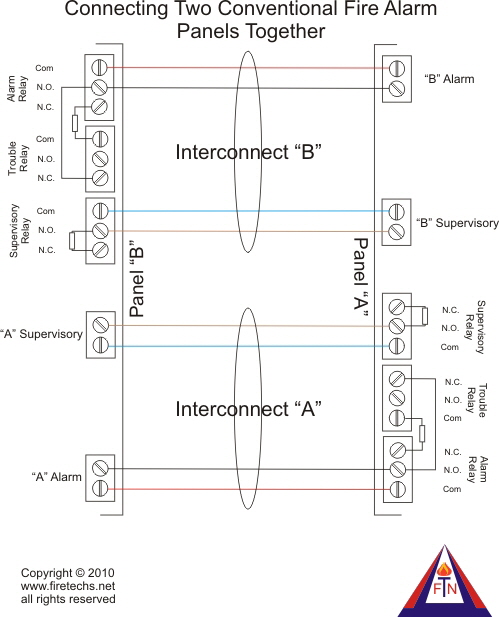

How do you properly connect two fire alarm panels together? LARGE NETWORK SYSTEMS will usually require two conductor twisted shielded cable in a Class "A" configuration. We would suggest that hooking TWO CONVENTIONAL PANELS together so that they monitor each other for "trouble", "supervisory" and "alarm" conditions (all of which are required under the present Building Code) requires two separate runs of five conductor cables. You'll also require two spare initiating zones and unused alarm/trouble relay contacts in each common control. Mark each five conductor cable end with "FA Interconnect-A" and "FA Interconnect-B" respectively. At the designated "B" panel, remove the end of line resistors from the two spare zones. The fire alarm should indicate a "trouble" condition on both zones. Take the "A" cable and connect the red and black wires to the first spare zone (this will become "A Panel Alarm"). Connect the blue and brown wires (of the same cable "A") to the second spare zone (this will become "A Panel Supervisory"). Reserve the green. Now connect the "B" cable red and black wires to the "common" and "normally open" terminals of the free "alarm" relay. Take one of the end-of-line resistors you removed from the "A" panel spare initiating zone and connect one end to the "common" terminal of the free "trouble" relay. Connect the other end of the resistor to the "normally closed" terminal of the "alarm" relay. Connect the "normally open" terminal of the alarm relay to the "normally closed" terminal of the "trouble" relay with a short piece of wire. Take the blue and brown wires from "B" cable and connect them to the "common" and "normally open" terminals of the "supervisory relay". Connect the second "A" panel end of line resistor between the "normally open" and "normally closed" terminals of the same "supervisory relay". At the designated "A" panel, the fire alarm should indicate a "trouble" condition on both "spare" zones (you have relocated the end-of-line resistors to the "B" panel). Take the "B" cable and connect the red and black wires to the first spare zone (this will be designated "B Panel Alarm"). The zone trouble will clear when "B" panel is restored to normal "trouble free" condition. Take the brown and blue "B" wires and connect them to the second spare zone ("B Panel Supervisory"). This zone trouble should clear. Now take the red and black wires from designated "A" cable and connect them to the "common" and "normally open" terminals of the free "alarm" relay. Connect one of the "B" panel end-of-line resistors to the "common" terminal of the the "trouble" relay. Connect the other end of the end-of-line resistor to the "normally closed" terminal of the "alarm" relay. Connect a short piece of wire between the "alarm" "normally open" and "trouble" "normally closed" terminals. Connect the remaining "A" cable blue and brown wires to the "common" and "normally open" terminals of the "supervisory" relay. Connect the last "B" panel end-of-line resistor between the "normally open" and "normally closed" terminals of the same relay. We've provided a diagram (they say a picture's worth a thousand words, after all): NOTE: This is a suggested method that ensures both fire alarm systems monitor each other for "trouble", "supervisory" and "alarm" events. In this example, a common "trouble" (i.e. zone fault) on one panel will result in a zone fault on both. The "originating" panel will have two zone faults in this instance. As long as the wiring between the two panels remains intact an "alarm" condition will always over-ride a "trouble" (Additional zone programming may be required). Older panels may not be capable of providing a separate "supervisory" output but it's important that both common "trouble" and "alarm" conditions are shared between them.

Both panels should now be trouble free. If they're not, check that you've connected everything as noted above. If the terminal blocks on either panel's "alarm", trouble" or "supervisory" relays are of the "unpluggable" variety, removing any one block will cause a "trouble" condition to appear on both panels. What do you do with the two pairs of "green" wires left? Terminate them to the respective panel ground, of course. Resetting after an alarm event is fairly simple. Most modern panels allow you to "bypass" or "disable" the alarm relays. You'll have to do this on only one of the panels (the one that initiated the alarm). Reset the "follower" first, then come back to reset and re-enable the alarm relay on the initiating panel. Don't forget, your work may require you to pull proper permit(s) (check with your local jurisdictional authority) and must be verified to CAN/ULC-S537! |

|

||||||||||||||||||||||||||||||||||||||||

|

When you're upgrading a fire alarm system from a conventional control and devices to a fully addressable system (with analogue devices), do you have to follow today's fire code to ensure everything passes? Believe it or not, I get asked this question a lot (it's often phrased a little differently though). When a building owner decides to upgrade the fire alarm system, a number of code provisions and requirements will automatically "kick in". The Fire Code (Provincial or National) doesn't dictate installation requirements. It also doesn’t mention the Standard for Verification of Fire Alarm Systems (CAN/ULC-S537), so essentially transfers no jurisdictional authority. That falls under the auspices of the Building Code as well as CAN/ULC-S524 (Installation Standard for Fire Alarm Systems). On an existing building, however, the local fire authority does maintain jurisdiction, and will usually require you consult with them so that they can ensure appropriate measures are taken to safeguard the public who may be using the building while you’re engaged in your work. The short answer is, YES. Any devices you install will have to meet both of the aforementioned requirements, but in the case of a voluntary upgrade, additional provisions may also come into play. For instance: Some municipal regulators will allow a straight equipment swap without regard to proper detector spacing or placement. You'll have to check with your local authority. You can also review an example of what the City of Vancouver has to say on the subject in their Bulletin 2006-004 BU/EL. |

|

||||||||||||||||||||||||||||||||||||||||

|

Can end-of-line resistors (for multiple circuits in a room or area) be mounted in one box? What's the maximum mounting height for an end-of-line resistor plate? We'll reference the definitive answer in CAN/ULC 524:2019 (Standard for Installation Standard of Fire Alarm Systems) Section 47 "End-of-Line Devices" Clause 47.1 reads: “Except as permitted by 47.2, end-of-line devices for electrical supervision shall be located in a separate enclosure, installed not more than 1800 mm above finished floor level measured from the centre of the end-of-line device, and located beyond the last device in the circuit or terminated in a control unit or transponder.” From my perspective, the interpretation of this sentence is pretty clear. The Standard assumes that the end-of-line device is mounted on an approved and Listed plate but also allows for it to be installed inside either the common control or related transponder enclosure. Further clarification isn't provided but as a Verifying Agency I would accept termination on a proper terminal block affixed to the inside of either of the aforementioned equipment housings. The only other exception to mounting the end-of-line resistor on a plate is Sentence 5.13.2: “End-of-line devices which serve a single field device on a circuit may be located within that field device provided that the end-of-line device is accessible for inspection and voltage testing.” |

|

||||||||||||||||||||||||||||||||||||||||

|

When connecting the heater of an outdoor fire alarm annunciator, is it acceptable to tie into the fire alarm system’s power supply (circuit disconnecting means)? Most definitely NOT! CAN/ULC-S524 stipulates that the fire alarm system must be serviced by a dedicated circuit. Many technicians (including those that are factory trained on the subject equipment) feel that a tie-in to the fire alarm AC circuit is an acceptable means of ensuring the power to the annunciator heater is not inadvertently compromised. This is not the case! I have seen a number of transformer failures where the secondary windings have “opened” without affecting the primary side and thereby tripping the breaker (some transformers may even employ a fused secondary). The proper way to monitor power to the annunciator heater is through an appropriately rated low voltage relay connected to the secondary output (preferably located inside the annunciator enclosure in order to supervise the wiring to the heater as well). The fire alarm system can supervise a normally closed contact on the relay (which would trigger “open” – or show as “normal” when energized) through a latching supervisory input on the common control. You could parallel this connection to the same circuit monitoring the building’s sprinkler heat trace if you’ve run out of available zones (just make sure you make the appropriate change to the zone descriptor). Special NOTE: If you come across a fire alarm control that has a transformer (other than the systems primary power supply transformer) installed and which would invariably be paralleled to the system's main AC bus, you must RED TAG the panel. An "after market" installation of this type violates the ULC listing on the panel. Inspector's Tip: If the power to the annunciator heater goes down when you trip the breaker for the fire alarm system, the installation is in violation of ULC/CAN-S524. |

|

||||||||||||||||||||||||||||||||||||||||

|

How do you tie in (interconnect) door holders on a fire alarm system? Most modern fire alarm common controls manufactured today utilize common "on board" relay contacts that are rated at 24 volts DC. They are designed to interface with a fire alarm communicator for offsite monitoring of trouble, alarm, and supervisory conditions. In many instances, you must provide additional relay contacts to handle things like fan shutdown, fire dampers, etc. 110VAC door holders - Must utilize a 24VDC relay contactor that is triggered by a relay on the fire alarm's common control. Under no circumstances should you run the 110VAC for the door holder into the common control cabinet (although there are a number of older systems out there in which this was perfectly acceptable, electrical codes have changed). You must install the relay contactor into a separate box and ensure you maintain a physical separation between the high voltage and low voltage terminals. IMPORTANT! The door holders must utilize a 110VAC source that is separate from the fire alarm system. 24VAC door holders - Must utilize a 24VDC relay contactor that is triggered through the fire alarm's common alarm relay as well. You can install a relay block into the common control cabinet, but the door holders must be powered by a 24VAC source that is independent of the fire alarm system. Ensure that the cable entry for the 24VAC into the fire alarm common control enclosure complies with the manufacturer's instructions for non-power limited wires. Signal Circuit Relays - For retrofit installations (where it may not be possible to run wires all the way back to the common control), Edwards (GE Security) manufactures the only UL/ULC listed signal (NAC) circuit relay module for use on any conventional supervised signal (NAC) circuit. The unit is listed as a "6554 Series Fire Alarm Relay". The relay contacts are rated at 120VAC or 30 VDC, 5 amps inductive, 3 amps resistive. The unit mounts inside a standard two gang (4x4) deep box and comes complete with a appropriately labelled stainless steel cover. You must exercise caution when employing this relay to trip anything other than a door holder. Most new signal appliances don't ring continuously, but are set to pulse temporarily, and some are programmed to silence manually. When either of these circumstances occur, the relay will "follow" the operation of the NAC circuit (in which case things like fan shutdown, elevator recall, fire dampers may not function in the manner required by code). There is a "workaround" for this however. You can employ a latching relay contactor on the circuit. This will require the operator to manually reset the device once the fire alarm system has been restored. NOTE: If you're going to be employing a remotely mounted latching contactor, please ensure that appropriate instructions for resetting the circuit are posted on the fire alarm control (and/or remote annunciator) and that those instructions also include the location of the modules used to perform the required function. |

|

||||||||||||||||||||||||||||||||||||||||

|

How many sprinkler tamper switches can you terminate to a single initiating zone on a fire alarm panel? The magic number is set by your local AHJ, applicable building codes, and standards but averages around eight. Most AHJ's would like to see separate annunciation for each switch or valve within a common sprinkler room and this is often possible with an addressable system panel's liquid crystal display (LCD). At the very least, they will insist on having a separate zone for the back-flow preventer which often utilizes two switches (one on the inlet side and one on the outlet side) or the main water entry valve. You must use common sense when laying out your sprinkler zones and the same applies to the control valves inside a common sprinkler room. Identifying a misaligned valve (or defective switch) can become more time consuming when they're common to a single zone. NOTE: NFPA 72 allows for the connection of up to twenty (20) supervisory devices on a single conventional input circuit. |

|

||||||||||||||||||||||||||||||||||||||||

|

Can you review the relevant codes regarding installation of in-suite signaling appliances and signal circuit fault isolation devices? The British Columbia Building Code (BCBC) reflects a good deal of the Canadian Building Code with a few "twists" here and there (usually for the better). In Vancouver you also have to deal with the Vancouver Building By-Law (VBBL). Then there's CAN/ULC-S524 (The Installation Standard for Fire Alarm Systems). Let's examine some of these codes. BCBC 2018, VBBL 2017, CAN/ULC-S524-14 Clause 4.3.1.5 of CAN/ULC-S524-14, stipulates that "opens" or "ground faults" on one circuit shall not interfere with the operation of other circuits in the same system, and that “such faults shall initiate a trouble signal”. Clearly, the intent of the authors of this section was to preserve the functionality of the system as a whole even if one device (or circuit) was compromised by either of the forgoing fault conditions. This becomes more complicated when it involves signaling appliances located in a suite. The 2005 National Building Code had relaxed the requirement to employ isolator modules on signal circuits serving residential suites as long as a Class "A" loop is employed and the circuit servicing the suites is separate from the one serving the common hallways. An "open" anywhere in the loop will still allow the other signaling appliances on the same circuit to sound. On the surface this is considered "better practice" as an individual would have to compromise all of the buzzers/speakers in his suite to effectively silence any alarm or announcement. If, for instance, he just removed one, any others in the same suite served by the Class "A" circuit would still be fully functional. BCBC 2006 (NBCC 2005) Section 3.2.4.18(10): “Audible signal devices within a dwelling unit or a suite of a residential occupancy shall be connected to the fire alarm system a) in a manner such that a single open circuit at one device will not impair the operation of other audible signal devices on the same circuit that serve the other dwelling units or suites of residential occupancy, or b) on separate signal circuits that are not connected to the devices in any other dwelling unit, public corridor or suite of residential occupancy.” BCBC 2018 (NBCC 2015) Section 3.2.4.18(9): “In a building or part thereof classified as a residential or care occupancy, a) separate circuits shall be provided for audible signal devices on each floor area, and b) audible signal devices within dwelling units or suites of residential or care occupancy shall be wired on separate signal circuits from those not within dwelling units or suites of residential or care occupancy.” Unfortunately a "short" condition on the circuit will compromise the entire circuit unless isolators are employed. While BCBC 2006 didn’t take this scenario into consideration (this includes BCBC 2018), the VBBL 2007 introduced this safeguard which the 2017 edition continues. VBBL (2017) Sentence 3.2.4.19.(8) states: “An audible signal device located within a dwelling unit or suite of a residential or care occupancy shall be connected to the fire alarm system a) in a manner such that a single open circuit or short circuit at one device will not impair the operation of other audible signal devices on the same circuit that serve the other dwelling units or suites of a residential or care occupancy, or b) on separate signal circuits that are not connected to the devices in any other dwelling unit, public corridor or suite of a residential or care occupancy.” BCBC 2018, CAN/ULC-S524-14 BCBC 2018 Section 3.2.4.19 is called Audibility of Alarm Signals and reads in sentence (8): “Audible signal devices within a dwelling unit or a suite of residential or care occupancy shall be connected to the fire alarm system a) in a manner such that a single open circuit at one device will not impair the operation of other audible signal devices on that same circuit that serve the other dwelling units or suites of residential or care occupancy, or b) on separate signal circuits that are not connected to the devices in any other dwelling unit, public corridor or suite of residential or care occupancy. (See Appendix A.)” Installers must ensure the isolators are mounted OUTSIDE of the suites they serve. CAN/ULC 524:2019 Section 49 Suite Fault Isolators details several requirements: Sentence 49.2 reads “Each fault condition shall be separately applied and removed and the control unit returned to normal before the next fault condition is applied, except where operation under multiple fault conditions is required. Suite fault isolators shall be installed outside of the suite protected by the device.” “Shall” is an imperative. However one interprets this, the imperative in any fire alarm system design demands survivability of the signaling means. Vancouver has been a leader in many Canadian communities in addressing this very important issue. I believe it is "good Engineering practice" to ensure a Life Safety System remains as secure from compromise as we can make it. Clearly, suite isolators should be utilized to ensure the proper functioning of the fire alarm system. You may wish to read a bulletin issued by the City of Vancouver which clarifies their position on the subject HERE. |

|

||||||||||||||||||||||||||||||||||||||||

|

Can security wires be run with fire alarm wires in Canada? We interpret this question to mean: Can you run fire alarm wire and security alarm wire in the same wire raceway? It’s not common practice for security alarm installers to “mess with” other wiring that’s already in place in a building. That’s not to say that I haven’t seen lots of security wire tie-wrapped to existing conduit runs (or even run alongside the TV cable guy’s wire). Current Electrical Code doesn't allow you to mix the two in the same raceway, however. Keep in mind that many fire alarm systems sold today have the ability to provide zones and circuits programmed for building security components and the new mass notification technology will more than likely result in some significant changes to the Codes on both sides of the border. Always follow good wiring practice when installing/running cable! |

|

||||||||||||||||||||||||||||||||||||||||

|

Who has final authority to accept a fire alarm system installation? The answer to this question can be abbreviated into three simple initials: A H J (short for the "Authority Having Jurisdiction"). In Canada, on new installations, that is the Building Inspector, the Electrical Inspection Authority (or a combination of both). On renovation/upgrades, it's the municipal Fire Chief (usually in co-operation with the Electrical Inspector). All of these agencies however, rely on one individual's report and written comments before an occupancy permit can be issued. On new installations, not even the Design Engineer will sign off without this all important report. The onerous task of determining whether-or-not a fire alarm system (or a component added to it) meets all the installation and performance criteria is the trained professional technician performing the Verification. This individual is the acknowledged expert upon which everything hinges. He is the one charged with ensuring that all aspects of the installation meet the code requirements, applicable standards, and the manufacturer's testing criteria. The verification technician's job is pretty cut and dried. There is no "grey area" in any of the codes or standards that reference a fire alarm system installation. As a verifying authority, it is extremely important for the technician to understand this. No AHJ will dispute your decision to reject an installation that doesn't conform to the standard regardless of whether an Engineer has "designed" it that way, or a municipal "plan checker" has accepted it. Hopefully you will have had an opportunity to discuss what you perceive are issues that may hinder your acceptance of the system well before the final nail is driven and the painting completed. It is for this reason I have always advocated a verification agency gets involved at the start of a job (even as early as the plan acceptance process). Nobody likes "surprises" at the end of a job. Not only can they be costly in terms of "correction", the delays they represent could wind up penalizing the contractor. |

|

||||||||||||||||||||||||||||||||||||||||

|

What's the code requirement for battery backup in a fire alarm system that's tied into a building's emergency generator? Canadian relevant codes/standards are CSA C282, CAN/ULC 524:2019. The answer to this question isn't as straight forward as it would seem. CAN/ULC-S524 accepts an emergency power generator as long as it can provide the requisite twenty-four (24) hour stand-by (or supervisory) current and then power they system in "full alarm" for the time required as it applies to the building's height and occupancy class. This means that it would be perfectly acceptable to provide only enough standby battery capacity to power the system during the "start-up" and "full power transfer" phases of the generator. That's the legal code requirement IF certain other criteria are met. These include the fact that the generator must be monitored for "trouble" and "operation" by the fire alarm system and that the equipment must be listed/certified by an acceptable agency and be installed, maintained and tested in accordance with the code requirements and the manufacturers instructions. Additionally, the fire alarm Verifier is now responsible to ensure that the generator’s low fuel trouble set point triggers at a level where the required building code operation is no longer available (see Section 32.8 of CAN/ULC 537:2019). The forgoing represents the "correct" answer to the question but let's not stop there. Can you depend entirely on this method? There are a number of other considerations that must must be factored into this answer which often creates the confusion people encounter when they get different interpretations from individuals that represent the various agencies and stake holders involved. Some will go strictly with the Code/Standard requirements while those of us in the LIFE SAFETY profession tend to go with something called best practice. You'll often see these two words used when a particular Code or Standard lends itself to more than one interpretation, and you'll also see them used when a question has more than one right answer. Best practice simply means utilizing the best, safest, and most effective method (or solution). Let's look at some basic facts. An engine driven generator comprises a myriad of moving parts that are all required to work in concert to achieve the end result. A failure of any one part could mean that either the generator won't start, or it will fail to deliver the rated power to the transfer switch. The transfer switch is another mechanical device in the line to the emergency power distribution centre. The generator depends on a source of fuel which could comprise a large storage tank for diesel fuel or a direct connection to a local gas main (if the engine has been set up to use natural gas). The quality of the maintenance, age of the equipment, serviceability of the charging system, starter batteries, quality and quantity of available fuel... The list goes on. A breakdown anywhere in this chain will result in the failure of the emergency power system to deliver the the required standby capacity stipulated by the Standard. The clincher in all of this is that most emergency power systems (unless they are in a health care environment) only provide sufficient capacity to meet the Building Code requirement of “at least two hours” - Section 3.2.7.8 of BCBC 2018 - “Emergency Power for Building Services” (other Provincial Codes should have similar wording). The standby and alarm current requirements for the fire alarm system is seldom factored into the equation. Best practice would favour a simpler solution and eliminate the assumptions you are often forced to make surrounding the proper care, maintenance, and operational readiness of the generator (a “trouble free” annunciator should never be the basis for assuming the generator will work). The standby battery - properly sized - affords the most cost effective, simplest, and SAFEST method of ensuring the fire alarm system meets the requirements of the standard. |

|

||||||||||||||||||||||||||||||||||||||||

|

Does the fire alarm circuit breaker have to be painted red and "locked"? In many cases this is a jurisdictional requirement. There is nothing in either the Provincial building code or CAN/ULC-S524 (Installation Standard for Fire Alarm Systems) that actually stipulates it must be coloured red. You have to look in the Canadian Electrical Code to find it (specifically Rule 32-108). The fire alarm system's circuit disconnecting means must be easy to identify, coloured red, and it must be “lockable” in the “on” position. There are several reasons for this, the most important being that we don't want it inadvertently turned “off”. |

|

||||||||||||||||||||||||||||||||||||||||

|

An Electrical Engineer is insisting on locating conduit entries for the common control data, communication, and addressable field devices into an area of the cabinet that the manufacturer's installation instructions stipulate is reserved for non-power limited wire (AC and municipal tie). Can you review the requirements of CAN/ULC-S524 (and relevant codes) and advise? Sure. There are a couple of standards this Engineer should reference: CAN/ULC-S527 and CAN/ULC 524:2019. The latter's Clause 7.8 states: “Field wiring entry points for the various circuits and required circuit separations, shall be in accordance with the manufacturer's published installation instructions and CSA C22.1, Canadian Electrical Code, Part 1, Safety Standard for Electrical Installations, Section 12, Wiring Methods.” The manufacturer's installation instructions are presented in the documentation accompanying the fire alarm panel and usually references diagrams indicating specific wiring entry points and termination procedures. The concern here is that power limited wire will enter an area of the common control which has been designated for non-power limited wire. It is doubtful that a panel terminated in this fashion will pass the verification. NOTE: It's been pointed out to me that Canadian Codes do not recognize "Power Limited Circuits". While this is true, I believe that it's considered BEST PRACTICE to follow the recommendations of the manufacturer (or the specific instructions presented in the relevant wiring and installation instructions) when determining your wire entry points and common control wire routing. What you should do: Suggest to the Engineer that wire entry points into listed control equipment must be in accordance with the manufacturer's published installation instructions. I would suggest that you do this IN WRITING and back it up by attaching the relevant sections of the Code/Standard and any other supporting documentation (i.e. copy and include the pages from the installation manual that indicate the proper cable entry locations). This way, when the doo-doo does hit the fan, nothing should wind up sticking to YOU! |

|

||||||||||||||||||||||||||||||||||||||||

|

How many initiating devices can you have on a fire alarm system? For the answer to this question, we'll have to deal with a number of different factors. Wire size, type of devices (i.e. whether they derive power from the circuit as is the case with two wire type smoke detectors), distance to the end of line resistor, whether or not the cable you're using is shielded, etc. As you can see, the answer isn't as cut and dried as you might have thought. The manufacturer usually imposes limits on the number of two-wire smoke detectors you can wire to an initiating circuit. In my experience that usually averages between 20 and 30. Contact type devices such as manual pull stations, heat detectors, flow switches, sprinkler valve tampers, etc. don't draw power from the panel so (in Canada) you're only limited by CAN/ULC 524:2019 Clause 7.6: “The voltage drop and power dissipation on any circuit shall not prevent the proper operation of that circuit and shall be in accordance with the manufacturer's published installation instructions.” Keep in mind that best practice may suggest you consider adding additional initiating zones along with those extra detectors (particularly if the job involves new construction). Not only will this help you troubleshoot a potential problem, the responding authority will have an easier time as well. |

|

||||||||||||||||||||||||||||||||||||||||

|

Are there any fire alarm relays listed for tripping from a notification circuit? As a matter of fact, there is! It's manufactured by GE Security/Edwards and it's listed as a "6554 Series Fire Alarm Relay". The relay contacts are rated at 120VAC or 30 VDC, 5 amps inductive, 3 amps resistive. The unit mounts inside a standard 4x4 deep box and comes complete with a appropriately labeled stainless steel cover. NOTE: You must exercise caution when employing this relay to trip anything other than a door holder. Most new signal appliances don't ring continuously, but are set to pulse temporarily, and some are programmed to silence manually. When either of these circumstances occur, the relay will "follow" the operation of the NAC circuit (in which case things like fan shutdown, elevator recall, fire dampers may not function in the manner required by code). There is a "work-around" for this however. You can employ a latching relay contactor on the circuit. This will require the operator to manually reset the device once the fire alarm system has been restored. In this scenario, appropriate instructions must be posted on the fire alarm control (and/or remote annunciator). |

|

||||||||||||||||||||||||||||||||||||||||

|

What's "the Code" say about monitoring sprinkler valves and systems (generally)? This question has been reworded somewhat from the one entered into Google which was: “What's the fire code to monitor tamper switches grouped together?”. I hope I've interpreted it correctly. There are several Sections that cover the monitoring of sprinkler devices (most of which are derived from the Canadian Building Code so the section numbers should be identical across most Provincial/Territorial Jurisdictions). 3.2.4.7(2) reads: “A fire alarm system that includes waterflow-indicating devices shall be designed to notify the fire department in conformance with Sentence (4) when an alarm is initiated.” 3.2.4.7(4) reads: “Notification of the fire department, as required by Sentences (1), (2), and (3), shall be provided in conformance with CAN/ULC-S561, "Installation and Services for Fire Signal Receiving Centres and Systems.” 3.2.4.9.(3) states: “An automatic sprinkler system shall be electrically supervised to indicate a supervisory signal on the building fire alarm system annunciator for each of the following: a) movement of a valve handle that controls the supply of water to sprinklers, 3.2.4.9.(5): “Indication of a supervisory signal in accordance with Sentence (3) shall be transmitted to the fire department in conformance with Sentence 3.2.4.7.(4).” Then there's 3.2.4.9(2) which reads: “If a fire alarm system in a building is required to have an annunciator by Sentence 3.2.4.8.(1), except for hose valves, all valves controlling water supplies in a standpipe system shall be equipped with an electrically supervised switch for transmitting a trouble signal to the annunciator in the event of movement of the valve handle.” |

|

||||||||||||||||||||||||||||||||||||||||

|

Where should a fire alarm control panel be installed? The simple answer is: "Someplace warm and dry". Fire alarm panels are usually located in a central INDOOR location so that the building occupants and first responders can easily access the various control functions such as exhaust and pressurization fans, elevator recall, door holders and release mechanisms, etc. In large buildings, it helps to have this at or near the main entrance so that the TROUBLE, SUPERVISORY, or ALARM information can be quickly discerned and the appropriate response or action(s) determined. Many common controls are located in the main electrical room in which case they would employ some form of remote annunciation at or near the structure's main entrance. In all cases, access to the control functions must be restricted to authorized personnel through the use of cabinet locks or (for some of the higher level functions) pass codes. Section 3.2.4.8 of the British Columbia Building Code states: “Except as permitted by Sentences (3) to (5), an annunciator shall be installed in close proximity to a building entrance that faces a street or an access route for fire department vehicles that complies with Sentence 3.2.5.5.(1).” |

|

||||||||||||||||||||||||||||||||||||||||

|

How do you add an isolator module to an existing fire alarm panel? The answer to this question is in the instruction sheet that usually comes with the unit. This also includes a wiring diagram which identifies the terminal connections for you. If you're adding an isolation module to either a Chubb/Edwards (formerly GE Security) or Simplex addressable system SLC (or data) loop, it will require a change in the software to properly identify the unit. Mircom, Secutron, FireLite, Notifier, and Potter utilize "dumb" loop isolators. That means there's no "smarts" in them, just a simple relay and circuitry to identify a "low" or "short" condition on the output. Notification (bell) circuit isolator modules are also "dumb" devices and don't require any special programming to install. Remember that (in Canada a least) the addition of any device on a circuit is considered a modification of the fire alarm system and will trigger the requirement for a Fire Alarm Verification Inspection! |

|

||||||||||||||||||||||||||||||||||||||||

|

Is it permissible to have different audible signal devices in the same building? In Canada, the National Building Code as well as the BCBC appears to be fairly silent on this issue (I'm pretty sure that other Provincial Codes don't specifically address this issue either). You have to go to CAN/ULC 524:2019 (Standard for Installation of Fire Alarm Systems) for the answer. Sentence 39.7 reads: “Except as permitted by 52.4.5, audible signal devices within a building shall generate similar sounds and sound patterns when activated.” Are there exceptions? Yes. There are two notable ones actually: 1) In-suite sounders are often found on fire alarm systems that employ bells or gongs in the common area spaces of a residential building. The interpretation most Verifying Agencies place on this section is that you can't "mix" alarm sounds within a building's public spaces (you can't put up horns with bells in the hallways, parkades or common areas). It's interesting to note that a larger number of Architects and Design Engineers are moving more towards employing horns and non-silenceable buzzers in public corridors and areas instead of the standard red fire bell. Not only do they meet (and often exceed) the required sound pressure levels, they're far more attractive and less prone to tampering. If you wish to change out a buildings existing bells (upgrade them to horns/buzzers), you should engage in a consultative process between the local AHJ and a Design Engineer (who will ensure the spacing requirements and sound pressure levels meet the current Installation Standard). 2) Sentence 52.4.5 states: “Audible signal devices providing local notification of fire suppression system operation shall produce a sound that is different from the building fire alarm system audible signal devices.” |

|

||||||||||||||||||||||||||||||||||||||||

|

What is the maximum height for a fire alarm pull station in Vancouver? We’ve produced a handy Field Device Wiring Guide for you to reference that also covers the changes adopted in the 2014 published edition of the Installation Standard, which have carried forward in CAN/ULC 524:2019. CAN/ULC-S524-06 Sentence 5.2.1 reads: “Manual stations shall be installed not less than 1200 mm and not more than 1400 mm above the finished floor level measured to the centre of the manual station.” CAN/ULC 524:2019 Sentence 26.1 requires: “Manual stations shall be installed 1050 mm to 1150 mm above the finished floor level measured from the centre of the manual station.” What if you're replacing an existing manual station that's not installed to the current standard? In many buildings more than thirty years old, some manual stations are of the old style disk type which aren't even ULC Listed. In many instances, these units are often found on equally archaic three-wire unsupervised twelve volt fire alarm systems. None of these installations could be termed "deficient" as they probably met the Code requirements of the day. Replacing a defective manual station (as with any other similar fire alarm device) is a maintenance issue and not an installation one. NOTE: In older buildings, you can't do much about the mounting height (without extensive cosmetic damage to the wall), but you can do something about bringing the fire alarm system more into compliance by recommending the owner change out non-listed bells and manual stations with units that are ULC Listed. Such a recommendation should be noted in the "Recommendations" section of your annual test report. It may be prudent for you to also submit a copy of your report to the local Fire Department's Fire Prevention Office who may follow-up on it with a site visit to determine the suitability of requiring the owner to (at least) update the affected devices. |

|

||||||||||||||||||||||||||||||||||||||||

|

I'm an electrical contractor working in Vancouver on a fire alarm upgrade. We're installing an addressable fire alarm system from a well-known manufacturer with a local office. The subject of wiring for devices attached to the SCL loop as well as the remote annunciator required some clarification from the local rep, who advised that it was perfectly acceptable for us to use non-shielded cable for both. The rep went on to say that since the run to the annunciator is so short, we could even use a single five conductor 18AWG unshielded fire cable to terminate both power and data runs with no difficulty. My question is: Will this pass the verification test? The installation manual calls for twisted shielded pair to be used on the RS-485 communications loop for the annunciator. Whenever I get asked this question (and whenever I SEE something like this), I see RED! A manufacturer's REP (or technician) counseling someone to deviate from the published installation instructions should be (in my considered opinion) automatic cause for their immediate dismissal. What troubles me even more is the possibility that the system may be verified by the same individual that counseled the deviation in the first place and that, very often, the local branch office isn't aware of (or - in the worst possible case - might even turn a blind eye to) this dangerous practice. If you choose to follow the rep's advice, you may be exposing yourself to an unacceptable level of personal liability (try to envision the robot in the series "Lost in Space" frantically waving his arms and shouting: "Danger Will Robinson! Danger!"). The installation instructions forms part of the submittal required by ULC of the manufacturer in order to certify the equipment for use in Canada. Deviations from these instructions cannot be authorized by anyone other than ULC (and only after the subject equipment has been resubmitted for testing under the specified condition). Now some readers may be ready to point out that the Authority Having Jurisdiction could authorize such a deviation, but I have yet to see this happen (in my almost thirty years in this business). This kind of thing amounts to (at the very least) a "triple whammy" as you would be violating two (2) major ULC Standards and Section 3.2.4.5 of BCBC 2018 (in the case of Vancouver it's the VBBL). CAN/ULC 524:2019 (Fire Alarm Installation Standard) Clause 7.2 notes: “The installation of field wiring shall be in accordance with CSA C22.1, Canadian Electrical Code, Part 1, Safety Standard for electrical Installations, Section 12, Wiring Methods, and Section 32, Fire Alarm Systems and Fire Pumps, the manufacture’s published installation instructions, and the requirements of 7.4 through 7.14.” (underlined for emphasis). CAN/ULC 537:2019 (Fire Alarm Verification Standard) states in Clause 6.3.1: “Conductors extending beyond a control unit or transponder shall be inspected at all system field device termination points to ensure that the conductor type and gauge is in accordance with the equipment manufacturer's installation wiring requirements.” |

|

||||||||||||||||||||||||||||||||||||||||

|

Can fire alarm wiring be painted? Exposed fire alarm cable (free air run) is allowed in some circumstances (i.e. buildings of combustible construction). This doesn't mean that it's not "out there" in some other applications (such an installation may have met the "requirements of the day" on older installations). Painting fire alarm cable will alter it's tested flame exposure characteristics and may even contribute to more rapid spreading of a fire. In fact, you really shouldn't paint any exposed wiring in a building (for the same reason). Fire alarm cable must be protected from physical damage and as such is always run inside rigid EMT conduit or flexible "BX". You can paint either with no appreciable adverse affect. |

|

||||||||||||||||||||||||||||||||||||||||

|

Do you require a class "A" circuit for a fire alarm emergency communications riser? In Canada, the newest edition of CAN/ULC 524:2019 requires any circuit classified as a riser to be run as a Class “A” circuit. There are some pretty strict rules about how a riser is installed and what measures you have to employ to meet the test of system survivability. These have to do with maintaining proper fire separations, fire stopping, routing of cable, etc. For the purpose of this FAQ, we will defer to another reference mentioned in the 2019 published edition of the Installation Standard and that is “good engineering design”. Any riser serving multiple floor areas of a building must be run in a Class “A” configuration with isolators. For more information on this, please refer to our Special Report on Isolators. |

|

||||||||||||||||||||||||||||||||||||||||

|

Is it permissible to use a UL® listed fire alarm device on a Canadian system even if they're both made by the same manufacturer? In Canada, you can only use ULC® listed devices on a ULC® listed fire alarm panel. Conversely, you can't use a ULC® listed device on a UL® listed fire alarm panel in the United States. The "cUL®" mark is the only one that is recognized as having "no barrier" for use in either country. Using a non-listed device on a listed fire alarm panel is strictly forbidden and would invalidate the ULC® (or UL®) listing. CAN/ULC S524:2019 (Standard for Installation of Fire Alarm Systems) states in Clause 4.3: “Devices and equipment used in a fire alarm system shall comply with the following Standards: A CAN/ULC-S525, Audible Signal Devices for Fire Alarm Systems, Including Accessories; NOTE: If your employer is sourcing fire alarm product from an agency outside of your country's testing jurisdiction for use on a listed fire alarm panel, you cannot install it, and you cannot validate such an installation by accepting (or passing) it. |

|

||||||||||||||||||||||||||||||||||||||||

|

Does the Ontario Building Code allow for the installation of fault isolation modules above a T-Bar Ceiling? Neither the National Building Code or the Provincial ones stipulate exactly WHERE to mount fault isolation modules. For the answer to this question, you have to reference CAN/ULC524:2019 (Standard for Installation of Fire Alarm Systems), specifically Section 48 which is titled “Fault Isolators”. Clause 48.2 states: “Except as noted in Clause 48.3, fault isolators, shall be located in a separate enclosure and installed so as to be visible and accessible at all times.” (actual answer underlined for emphasis) The way I interpret this clause in the Standard is that you can mount the isolator IN the T-Bar, but not ABOVE it for the unit to meet the requirement of being “visible and accessible at all times”. There are some additional requirements as well (the least of which is the test to meet the required fire rating which most T-Bar ceiling systems fail to do). It's best for you to review all the clauses in this section of the Standard before you proceed with the installation. |

|

||||||||||||||||||||||||||||||||||||||||

|

What is the allowable distance between power and non-power (limited) cables? Inside most fire alarm control panels, manufacturers stipulate that you must maintain a 2.5" (10cm) separation. Most manufacturers provide conduit entry points for AC power and field wiring for signal, indicating, and data circuits. If the conduit entries haven't been die cut into the back-box, then you'll find the necessary details in the installation manual. It's important for any installer to familiarize him/herself with the manufacturer's installation guide to ensure optimal performance of the equipment they're setting up. You can also reference another FAQ on this subject HERE. |

|

||||||||||||||||||||||||||||||||||||||||

|

Can 120 VAC power for a fire alarm system be run in the same 1/2" conduit as the AC power for a security system or ULC Listed fire alarm communicator? |

|

||||||||||||||||||||||||||||||||||||||||

|

Where does it state that you can’t install fire alarm devices until the walls are painted? Nowhere. However, it DOES state on the housings of most fire alarm field devices: “Fire alarm device - DO NOT PAINT” Most building contractors prefer not to run the risk of having to replace a newly installed smoke/heat detector or suite buzzer because a painter decided the colour of the device didn’t quite match the decor. |

|

||||||||||||||||||||||||||||||||||||||||

|

What do you think about the application of Linear Heat Detection in an unheated attic (+30 to -40 Celsius)? The attic is going to be sprayed with fire retardant coating which will prevent the spread of fire, but we think a practical solution for detection is paramount. Conventional heat detectors are going to be a little bit hard to access for the purposes of annual testing. Please let me know what kind of engineering solution can be suitable for this situation. Interfacing a detection system similar to that produced by Protectowire with any conventional (or addressable) fire alarm panel isn’t extremely expensive. In the PDF provided, the “XLT” product is specifically designed for cold temperatures, but you would still have to anticipate the ambient temperatures in the attic IN THE SUMMER to be able to select the appropriately rated cable (for the high side). This might be difficult to do on a new construction project where you have no previous experience to draw upon. Furthermore, this product would have to be installed after any fire retardant was blown in as it cannot be painted, covered, or insulated. It also has to be installed very carefully to avoid abrasions to the insulation and tight bends (I know, I’ve worked with it and it’s a pain). I’m concerned with the fact that this product would be treated as a “fixed temperature” detector (for annual testing purposes) which could result in the failure to physically inspect the wire for damage (not that I’m suggesting fire alarm technicians are lazy - they just may be reluctant to go up in an attic space if temperatures are in excess of 30 degrees C). The requirement to test fixed temperature heats is in Section 5.7.3.3 of CAN/ULC-S536-04: “Each non-restorable heat detector shall have the circuits tested by simulating its electrical operation at the wiring connection.” The wiring connection referred to in the Standard would likely be located OUTSIDE of the attic space (particularly if the “Alarm Point Location Meter”, mentioned in the PDF, is utilized) which would make the testing convenient, but could encourage the omission of the visual aspect of the inspection. Keep in mind that in a sprinklered building the attic spaces are supposed to be protected. In this instance, it would likely be a dry sprinkler system (or a wet one employing an antifreeze loop), both of which would (should) annunciate separately at the fire alarm control panel. |

|

||||||||||||||||||||||||||||||||||||||||

|

If a fire alarm system is not required, can I still install one in my building and, if so, is what I install required to meet the Ontario Building Code? If you install a fire alarm system (whether it’s required for your type of occupancy or not), you must install (without exception) the equipment in accordance with CAN/ULC-S524-14 (Canadian Standard for Fire Alarm Installation). This applies to any Provincial/Territorial jurisdiction in Canada (for the time being). In British Columbia, we’re going to be enacting NBCC 2020 on December 31, 2023, which will reference CAN/ULC 524:2019. This requirement in referenced in NBCC 2015 3.2.4.5: “1) Fire alarm systems, including the voice communication capability where provided, shall be installed in conformance with CAN/ULC-S524, ‘Installation of Fire Alarm Systems’. 2) Fire alarm systems shall be verified in conformance with CAN/ULC-S537 , ‘Verification of Fire Alarm Systems,’ to ensure they are operating satisfactorily.” |

|

||||||||||||||||||||||||||||||||||||||||

|

Where can I find the testing form for the Canadian Fire Alarm Installation Standard (CAN/ULC-S524)? The form you’re looking for is actually part of another Canadian Standard, called the Verification of Fire Alarm Systems (CAN/ULC-S537). The current version is the “-13” one which you can download on our Forms Page! This has been amended to include devices that are mandated to be tested by the 2014 published edition of the Installation Standard. |

|

||||||||||||||||||||||||||||||||||||||||

|

What’s the difference in price between a proprietary and non-proprietary fire alarm system? Wow! Interesting question! Let’s explore the difference between the two system types this question actually mentions. First and foremost, there isn’t really one. Most system manufacturers research, design, engineer, and produce their own equipment (some, like Honeywell, Mircom and Potter) do final assembly here, but the circuit boards and constituent parts are actually manufactured elsewhere. Honeywell has facilities in Mexico, Potter equipment is largely manufactured in Japan (where all the really cool stuff comes from), and Mircom’s FX-350 utilizes field devices manufactured in England (God Bless the Queen!). System Sensor manufactures field devices and partners with various fire alarm panel manufacturers to produce active devices which utilize that company’s proprietary communication protocols. The essential difference between what’s termed proprietary and what’s not, is whether the manufacturer maintains a local (branch or regional office) and staffs it with factory trained technicians. For example: SimplexGrinnell, Siemens, Chubb-Edwards, and Mircom all fall into this category. On larger distributed type systems (often ones that employ Emergency Voice Communication and which may involve very complex programming), having a manufacturer employed factory trained technician working on the equipment is desirable (and essential to the proper functioning of the system). Invariably, the larger systems also have a greater cost (both for equipment and service). Chubb-Edwards, Mircom, and Honeywell (which markets the Notifier, FireLite, and Silent Knight products) also sell panels and equipment that’s more open-ended when it comes to programming and service. This results in the equipment being more readily accessible through wholesale distribution and through designated dealers (the latter of which receive the benefit of more in-depth factory training). What you should really be asking here is: How does my cost of service for equipment purchased from a manufacturer that maintains a local branch office (and factory trained technicians) compare to choosing more open-ended equipment? Manufacturer’s Office: Hourly charges as high as $250.00 and surcharges (a “truck charge” like the one Chubb-Edwards levies comes to mind). For actual service of the higher-end equipment (or material changes/additions that might involve reprogramming), you’re pretty well stuck (locked in to using their branch office). For annual service and testing, you’re free to use any fire equipment service provider you like, though. Open Ended Equipment: Competition dictates the service rate (and any surcharges can usually be negotiated). |

|

||||||||||||||||||||||||||||||||||||||||

|

How do you terminate shielded cable in a manual pull station (or other field device)? There are actually two potential scenarios presented by this question. In the first, the device being terminated is the last device in the circuit, in which case you wouldn’t do anything with the shield (or shield drain wire) except wrap it in some electrical tape so it won’t ever come into contact with the device box ground. The second involves junctioning the wire to continue the loop run to the next device in the circuit. This involves connecting the shield (or shield drain wires) together (in order to preserve the integrity of the shield) and taping them so that they don’t come into contact with the device’s backbox (or ground). Some devices may require you to terminate the shield (or drain wire) onto an appropriately labeled terminal. Follow the manufacturer’s instructions for the specific device you’re installing! |

|

||||||||||||||||||||||||||||||||||||||||

|

How many fire alarm bells are there in a typical elevator hoist way? None. Fire alarm bells are not considered a part of the elevator, or elevator’s fire detection system. There is usually a bell or audible sounder of sorts which passengers trapped in a stuck elevator can access. This is usually cab-mounted (and not attached to the hoist way). |

|

||||||||||||||||||||||||||||||||||||||||

|