Tech-News & Views

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

OUTDOOR FIRE ALARM ANNUNCIATOR INSTALLATION & INSPECTION

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

The issue of providing essential information regarding a fire’s location in a complex with a large footprint (or that may employ multiple storeys) has, up to today, been a fairly “easy fix” for our industry. Recent events have created a major conundrum which we, in the life safety equipment service community, are going to have to confront and ultimately provide viable solutions for. Normally speaking, as technicians, when a tool we’ve come to rely on is no longer viable, we simply save up and replace it. Unfortunately, an annunciator (even an UNLISTED one) is going to prove extremely difficult to simply “replace”.

INVESTIGATION

I approach every investigation I’m involved in in much the same way as I was taught when I was working as an aviation insurance adjuster thirty-four years ago. An important prerequisite for any investigator is to remain objective and ignore any preconceptions that might distract him from the careful gathering of evidence and subsequent examination of the facts at hand. You start with some preliminaries, take lots of pictures, determine the scope of the issue, interview some witnesses (or other experts), and formulate some conclusions that hopefully will prevent a repeat of the accident (or in this case come up with a viable solution that isn’t going to involve a major installation nightmare - an “easy fix”). Unfortunately, as we were quick to discover, it’s a problem that involves a much bigger issue and many more manufacturers. The “fix” is NOT going to be “easy”.

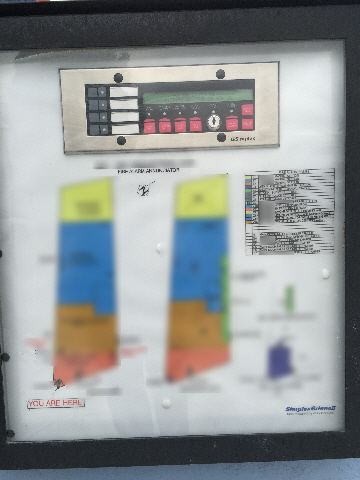

Outdoor Applications

|

|||||||||||||||

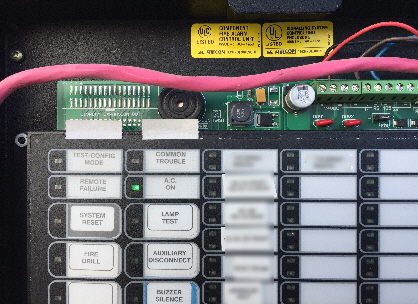

Outdoor misapplications of LISTED equipment involve more than just annunciators as you can see. Some rather loose interpretations of the Standards (in BC’s Lower Mainland, for instance) in the past have resulted in some rather unorthodox solutions to the Building Code requirement for First Responder local notification and control. I should clarify my comments in that I can also only speak for two jurisdictions in which I’ve actually worked in: British Columbia and Alberta (with the former enjoying all of my photo-journalistic endeavours when it comes to life safety systems because of recent advances in hand-held technology).

THE “M” FACTOR

|

|||||||||||

The ULC Listing

An extensive search of UL’s and ULC’s online directories yielded NO RESULTS for any of the specific equipment certification categories we entered, so we broadened it to just the name of the manufacturer (Mircom) and looked through every data sheet for a line item that referenced the BB-1001WP (or BB-1001WPR). Again, no results.

|

The Labels

There are six (6) annunciators that have similar labels all installed in the same complex. What do the presence of the labels mean? Mircom has launched their own internal investigation into the matter and are fully cooperating with ULC’s compliance office in an effort to determine how these labels came to be applied.

|

ULC

The Fire Technicians Network Report

On December 2nd, 2016 I transmitted an email to ULC. I attached a letter (also forwarded by registered mail) detailing the results of my preliminary investigation into the Mircom product, as well as what I uncovered regarding the misapplication of a number of other manufacturer’s equipment installations. We offered no conclusions, but made some very specific recommendations (six to be exact). They are:

1. UL/ULC should take immediate steps to identify the number of outdoor annunciator assemblies which have been installed outside of the original equipment manufacturer’s published installation instructions and guidelines. We would recommend the immediate publication of a Technical Service and Recall Bulletin (or other public service notification) through the UL/ULC website, the Canada Safety Council and Health Canada to deal with this issue.

2. UL/ULC should take immediate steps to identify the number of Mircom Technologies BB-1001WP/BB-1002WP annunciator installations which have been mislabelled with the UL/ULC Mark. While coordination with the Mircom Group of Companies and Canadian local jurisdictional authorities may be helpful in doing so, we also recommend the immediate publication of a Technical Service and Recall Bulletin (or other public service notification) through the UL/ULC website, the Canada Safety Council and Health Canada.

3. The installation of unlisted BB-1001WP, BB-1002WP, TH-101, and PS-3B equipment could also be tracked through the registered responses to the aforementioned Bulletin which would be filed by the owners, operators, jurisdictional authorities, and fire service companies familiar with the affected buildings within their jurisdiction and control.

4. The TH-101 heater must be properly certified as a listed assembly and its correct installation detailed (this should include an acceptable method for supervising the integrity of the heater’s auxiliary power circuit by the fire alarm system). The PS-3B Transformer must be included in the listing criteria if it meets the power requirements of the TH-101 unit.

5. The Mircom Group of Companies should engage an independent agency to perform testing/inspection of all outdoor annunciator installations identified in items 2 and 3, to ensure compliance with any remedial actions deemed necessary.

6. The Bulletins recommended in item 1 & 2 should also be circulated through the Canadian Fire Alarm Association (CFAA), the Fire Technicians Network (FTN), the Provincial Applied Sciences Technologists and Technicians Associations (ASTT), the Provincial Associations of Professional Geoscientists and Engineers (APEG), and all fire alarm equipment manufacturers distributing equipment that is ULC Listed for use in Canada. It is imperative that individuals performing Design, Inspection, Verification and Auditing functions of building life safety equipment are apprised of the equipment’s certification status and correct application.

A copy of our report was also transmitted to several Lower Mainland jurisdictions because it identified an issue that affected a number of OTHER manufacturer’s fire alarm equipment installations.

Mircom’s Response

Much to their credit, and our complete surprise, Mircom’s response to our report to ULC didn’t result in a letter threatening us with legal action. In point of fact, I can honestly state that their response has been nothing short of amazing. It started with a request for a meeting with me at their Maple Ridge branch office.

In attendence:

Mark Falbo, Mircom’s President,

Jason Falbo, Mircom’s Vice President for Engineering

Laurie Eisner, Mircom’s Vice President of Product Development

Alan Taaffe, Mircom’s Vice President for Canadian Sales and Service

Dave Clark, Mircom’s Maple Ridge Branch Manager

Wayne Doucette, Mircom’s Maple Ridge Service Manager

I was immediately struck by the open and forthright manner in the way they approached what was obviously the uncomfortable and disturbing subject of the misapplied labells. We reviewed the contents of my report and discussed some of the preliminary findings from their own internal investigation which the’ve implemented at their head office and factory. Mark was very quick to point out that, while transparency is both a positive and necessary step towards ensuring an acceptable resolution to the particular issue involving their equipment, it’s also going to be a key factor in expanding the focus of their entire engineering team in support of a more permanent, universal solution from which UL / ULC can implement the process of amending the relevant Standards to include the ability to properly test, certify and mark this equipment.

Since our meeting, I’ve exchanged a number of communications with Mircom’s management team as they work towards resolving the issues we identified, and which relate directly to their own manufactured products. Their efforts are currently being directed towards providing a viable retrofit alternative, that will likely involve the installation of a third party’s secondary enclosure, while they pursue a more permanent Mircom engineered and manufactured solution.

We will be revisiting this aspect of the story and will update our Bulletins page as necessary.

Their investigation into the mis-applied ULC Marked labels continues apace as well. They have assured me that they remain committed to the safety of all their customers past, present, and future, as well as to the public. I do not doubt this.

In our opinion, Mircom has responded responsibly to the concerns we voiced in our letter to UL / ULC, and, it should also be noted, have exceeded our expectations by offering to engage us in this process.

CODES AND STANDARDS

As of today’s date (December 15th, 2016), Canadian fire alarm installations must comply with the NBC 2010, CAN/ULC-S524-06 (Standard for Installation of Fire Alarm Systems), and Canadian Electrical Code C22.1-2012. I’m an advocate for a little more “future thinking”, however. Newer Codes and Standards are going to be referenced in the coming months that offer considerably more in the way of enhancement and clarification. I’m, of course, referring to NBC 2015, CAN/ULC-S524-14 (Amendment 1), and CEC C22.1-15. As you read this article, you will notice that we reference the newer Standards, which also happen to refer to CEC C22.1-12.

INSPECTION CRITERIA & GUIDANCE

I won’t repeat what’s already part of the report that’s been filed with ULC, since the gist of it has already been provided in this article.

Suffice it to say the purpose of this EXTRA! is to highlight a simple fact. The elephant in the room that has, up to now, been painted with the Mircom colours and logo, is actually part of a whole herd of elephants, each painted with a different manufacturer’s logo and colours. When they all stand together they form a multi-hued display that actually FILLS the room.

The key issue our preliminary investigation has identified is that the misapplication of listed equipment touches on more than one manufacturer’s products.

Can we all say, with absolute certainty, that this misapplication is the fault of the manufacturer? Does not the installer play some role in determining how the product is utilized? What about the Verifier? The (Registered or Certified) technician conducting the annual service?

More importantly, where is ASTTBC in all this? The CFAA?

The BIG QUESTION I have is: Why have we not had this conversation before? It seems to me that there’s a BIGGER elephant in the room; one that we’ve been ignoring for years.

Someone has to step up and provide the technicians conducting a Verification or Annual Inspection (to CAN/ULC-S537 or CAN/ULC-S536 respectively) with some basic tools and guidance. Whom do you imagine your customer is going to call when they have to address any concerns a jurisdictional authority might express? Shouldn’t you have the answers ready?

Through the open publication of this article, I’m also hoping to clarify some specific compliance issues for the jurisdictional authorities involved (both Building Officials and Fire Prevention Officers). I’ll be offering an unbiased, professional opinion, as well as an interpretation of the various Codes and Standards with the goal of promoting reasonable dialogue to determine a path to establishing policy(ies) that will address these issues in a comprehensive manner. I would suggest that the only successful resolution can be achieved if ALL the stakeholders are involved in this process.

First up, however, I’m going to remind the technicians reading this article, that we are OBLIGATED to ensure the safety of the public, and to report issues of non-compliance that we identify, to the local jurisdictional authority (the Fire Department for an existing building, the Building Officials for new construction). Your ability to identify non-compliance is largely predicated on your knowledge, vigilance, and integrity, which I have always suggested are the cornerstones of your professional practice (and which also happen to be part of the Fire Technicians Network Logo since it’s founding in 2007).

Note: I detail what (in my professional opinion) should be the MINIMUM installation, Verification and annual inspection criteria for outdoor mounted annunciators at the bottom of this page.

Annual Inspection

As a technician performing an annual inspection in accordance with CAN/ULC-S536, your primary role is to test, inform and make recommendations for repair, service or improvement. You are not in a position of authority (although many technicians I know will likely disagree with me), and therefore cannot force an owner to repair or correct a deficiency, or non-compliant item you happen to have identified during the course of an inspection. Knowledge of the Codes and Standards will definitely stand you in good stead when it comes to making an informative, accurate assessment of the fire alarm system’s operability. And proving that operability is what our Canadian testing Standard is supposed to confirm.

If you happen to be a member of a professional association (like ASTTBC or CFAA) it would behoove you to check with their published Practice Guidelines for any additional actions or recommended testing you should perform (ASTTBC’s RED TAG criteria offers some really good examples).

Verification

Technicians authorized by the jurisdictional authority they’re working in as Verifiers, are in the enviable position of being able to actually influence the acceptance of a fire alarm system (or a modification), but my personal experiences and observations, over the years I’ve been in this business, points to a disturbingly common practice of “accepting” an installation, while often turning a blind eye to any deviations from the Installation Standard or the system’s design. Many Verifiers are reluctant to raise issues that might flag an installation as deficient, because any repairs or modifications required as a result, could incur significant expense for the contractor and delay the project’s completion. Most building officials won’t accept an Appendix “C” that lists significant deficiencies, so the pressure to produce a “clear report” is enormous.

This problem actually stems from another common industry practice, and relates to the first time a Verifier usually sees the system he’s going to be testing. Can anyone guess when that is? It’s near the END of the project, when the fire alarm installation has been all but completed. Modifications, changes, or additions to the system that may be required to bring it into compliance with the Installation Standard (and design) now becomes problematic, and is often exacerbated by the belligerent insistence of the installing contractor to deliver an Appendix “C” that satisfies the local authority (a “clear” report). It’s a systemic problem that’s driven by economics and a tendering process that always seems to reward the lowest bid. The price of the system doesn’t make any allowance for meaningful interaction with the most important resource available to an installer (or the designer), a Verification professional that’s knowledgeable of the equipment, the installation criteria, the Codes, and the Standards.

An extra word of caution for those of you with the professional integrity and knowledge that might decide to REJECT a deficient installation, however. The company (or contractor) that hired you might well IGNORE your Appendix “C”. You see, nothing actually prevents him from hiring someone in your place, who may not share your professionalism, and who won’t scruple to submit the ”clear report” required. This actually happened to me on a recent Verification of a dual action suppression system in a freezer, when I rejected the model of linear heat detector that was installed. The contractor called another Verifier to the job, who gave him a “clean report” despite this, and the other installation issues I identified.

CYA

Note: This section is headed “CYA” which is an abbreviation for “Cover Your Ass” (no disrespect is intended).

Open communication between the local jurisdictional authority and the fire protection equipment service professional is essential to ensuring public safety isn’t being compromised. Listing deficiencies and making recommendations are also integral to the job, and are featured in all of the report formats you can download from our Library of FORMS. More importantly, you can also contact US with your questions and expect to receive an informed, Codes/Standards-based, unbiased response.

But before you all go off and start listing ANY outdoor mounted device as deficient, perhaps we should examine how, exactly, the term is defined in the Standards we’re all working with, and provide you with some guidelines into how YOU can determine it should be applied.

“Deficiency” in CAN/ULC-S537-13 is a defined term in Sentence 3.22. The identical definition appears in Sentence 3.15 of CAN/ULC-S536-13:

“For the purposes of this Standard, this term refers to a device or function that does not operate as intended.”

Can you identify any incorrectly installed fire alarm device, cover, ancillary device, control panel, or annunciator as deficient using this definition? Should you? If you can answer with a confident “NO” to either of the forgoing questions, you are not qualified to be conducting the Verification of a fire alarm system, nor should you be involved in any aspect of the annual inspection or service of building life safety equipment!

There are many resources at your disposal (including this website) that will help guide you along the path of professional practice (with the Standards themselves being the primary documents). If you’re a member of a professional association, you may have access to a Practice Guideline (as previoiusly mentioned). In the absence of the clear direction a Practice Guideline or Standard can offer, your local AHJ can also furnish you with information that will help you with issues regarding their expectations of how you should be determining the equipment’s acceptability or operability (and, who knows, may even furnish you with an enhanced definition of a deficiency). Keep in mind, the Authority Having Jurisdiction has the FINAL SAY on anything related to building life safety.

JURISDICTIONAL ACCEPTANCE

There are a plethora of Standards referenced in our National Building and Fire Codes and the Canadian Electrical Code, but there are really only FIVE that have anything to do with the INSTALLATION of a fire alarm system. These five Standards detail the installation, Verification, inspection, interconnection to a central fire receiving centre, and the integrated testing requirements for the building’s life safety systems.

Lets examine each one and provide you with some interpretations that should assist you in determining a viable strategy for dealing with the issue of any manufacturer’s outdoor-mounted fire alarm annunciators.

DISCLAIMER: Notwithstanding the opinions expressed below, a Building Official, a Fire Official, or an inspection department can interpret a Code or Standard and determine a course of action independently of another jurisdiction. This interpretation may also differ somewhat from what we suggest or recommend in this article. The intent of this article is not to establish hard rules for acceptance or rejection. Instead, we hope to encourage a more reasonable approach that provides a fair and balanced policy that won’t be prejudicial against the equipment of one particular manufacturer over another. To this end, we also wish to promote frank and open discussion between various adjacent jurisdictions so that technicians engaged in the Verification and annual testing of this equipment, are provided with a clear set of guidelines which establish mutually acceptable inspection criteria and reporting formats.

NBC 2015 requirements

This is bound to be where things are going to get a bit sticky. Why? Because the 2015 published edition of the Building Code hasn’t been adopted in any jurisdiction, province or territory in Canada (as of December 15, 2016 that is). The situation is further complicated by the fact that NBC 2015 references a Verification Standard (CAN/ULC-S537-13) that’s predicated on the 2006 published version of the Fire Alarm Installation Standard. The Installation Standard NBC 2015 references is the 2014 published version (CAN/ULC-S524-14 - including Amendment 1). This means that we have Verification and Inspection Standards that are significantly out-of-step with the way fire alarm systems are going to be installed. Moving forward, however, ULC has enabled the process where these important Standards are being cooperatively co-developed by the two Working Groups and Subcommittees involved. The 2020 editions of the National Building and Fire Codes will finally be able to reference harmonized versions of the Standards.

Our focus, in this article, is on the future as well (primarily because I’d have wound up having to rewrite it to incorporate the changes and different references when the new Standards are officially adopted).

DISCLAIMER: The version of the CAN/ULC-S537-13 Verification Appendix “C” forms available for download from the FORMS page in our LIBRARY has been amended to include additional testing parameters for fire alarm equipment installed to CAN/ULC-S524-14. We’ve also added some recommended inspection criteria to address the subject of outdoor mounted annunciators. These are the forms we will be referring to for the purposes of this article. Many of the reference Clauses we’ve provided have direct parallels in older versions of the Standards (they may be numbered slightly differently) and might incorporate some wording changes. Keep in mind that the newest version of ANY Standard is normally an improvement over the wording presented in a previous edition (the process of amending the wording is driven largely by the need to address specific requests for interpretation involving the same Clause.)

NBC 2015 articulates the ideal location for a fire alarm annunciator in Clause 3.2.4.9 Sentence (1):

“Except as permitted by Sentences (3) to (5), an annunciator shall be installed in close proximity to a building entrance that faces a street or an access route for fire department vehicles that compiles with Sentence 3.2.5.5.(1).”

Sentence (7) of the referenced Clause states:

“A fire alarm control unit installed in close proximity to a building entrance that faces a street or an access route for fire department vehicles that complies with Sentence 3.2.5.5.(1) is deemed to satisfy the requirement for an annunciator, provided all indicators required for an annunciator or trouble signal device are included in the control unit.”

Notice what the NBC DOESN’T say? (Hint) Does it say the annunciator has to be installed indoors?

CAN/ULC-S524-14 - Including Amendment 1 (Standard for Installation of Fire Alarm Systems) requirements

Section 5.2 is entitled “ANNUNCIATORS AND DISPLAY AND CONTROL CENTRES”

Clauses 5.2.1, 5.2.3, 5.2.4, 5.2.5 and 5.2.9 are the only ones that reference INSTALLATION requirements for these units:

“5.2.1 Annunciators and display and control centres shall be located in accordance with the requirements of the National Building Code of Canada.

5.2.3 Each annunciator or display and control centre required by the National Building Code of Canada and this Standard shall be permanently installed.

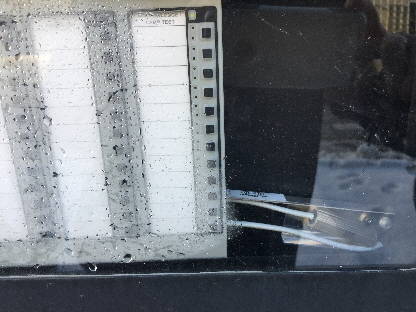

5.2.4 Visual displays and operating controls of the annunciator or display and control centre shall be located and logically grouped for convenient viewing, function and operation.

5.2.5 The visual displays and operating controls of the annunciator or display and control centre shall be not less than 600 mm and not more than 1800 mm above the finished floor level.

5.2.9 Operating controls on a display and control centre shall be located and arranged so as to be operated by authorized personnel only.”

Notice what the Installation Standard DOESN’T say? (Hint) Does it say the annunciator has to be installed indoors?

Lets examine some Clauses in Section 5.1 entitled “CONTROL UNITS AND TRANSPONDERS” to shine a little more light on the subject of annunciator installation.

Clauses 5.1.1 through 5.1.8 are the only ones that reference actual physical INSTALLATION requirements:

“5.1.1 Control units and transponder shall be installed in locations in accordance with the requirements of the National Building Code of Canada.

5.1.2 A clear space shall be maintained around control units and transponders to provide access for maintenance and testing in accordance with the manufacturer’s published installation instructions.

5.1.3 A minimum clearance of 1000 mm shall be maintained in front of control units and transponders.

5.1.4 The top of control units and transponders shall be not more than 2400 mm above the finished floor level.

5.1.5 Visual displays and operating controls shall be installed in accordance with Clauses 5.2.3, 5.2.4, 5.2.5, and 5.2.9.

5.1.6 Control units and transponders shall be permanently installed such that the control units and transponders cannot be inadvertently removed, powered down, or disconnected.

5.1.7 Except as permitted by Clause 5.1.8, control units and transponders shall be located in an area with an average ambient temperature range between 10 degrees (sic) C and 25 degrees (sic) C and were the relative humidity does not exceed 90%.

5.1.8 Control units and transponders installed in areas exceeding the ambient conditions noted in Clause 5.1.7 shall be listed for the environmental conditions in which they are installed.

NOTE: Refer to Appendix A (Informative) Explanatory Materials, Clause A5.18, Installation Environment, for listed temperature range.”

Notice what it says? (Hint) Does it reference an annunciator anywhere? YES! It specifically references Clauses 5.2.3, 5.2.4, 5.2.5 and 5.2.9 of the annunciator Section in Clause 5.1.5! Does it say anything about only mounting the annunciator indoors? I suppose you should infer that it does because it’s describing an annunciator installation that’s actually part of a fire alarm control panel display in this Clause.

CAN/ULC-S537-13 (Standard for Verification of Fire Alarm Systems) requirements

Lets focus on the testing parameters outlined in the referenced Standard.

Section 4.1 is entitled “GENERAL” and is preceded by this NOTE:

“Refer to Appendix C, Fire Alarm System Verification Records

4.1.1 Each fire alarm system shall be inspected and tested to confirm operability and that the installation is in accordance with the design and CAN/ULC-S524, Standard for Installation of Fire Alarm Systems.

4.1.2 Each control unit and transponder shall be inspected and tested in accordance with Section 5, Verification Procedure - Control Units and Transponders.

“Skip” ahead to Section 5.5, entitled “ANNUNCIATORS, REMOTE TROUBLE SIGNAL UNITS, DISPLAY AND CONTROL CENTRES”

This entire section is actually cross-referenced as checklist items in the CAN/ULC S537-13 Appendix “C” forms available for download from the FORMS link in our LIBRARY. Turn to page 11 of 19. The only references to INSTALLATION occurs in:

C5.8 G “Input wiring from control unit or transponder is supervised and of the correct type and gauge in accordance with the equipment manufacturer’s installation wiring requirements.”,

C5.8 L “Displays are visible in installed location.”,

C5.9 L “Displays are visible in installed location”, and

C6.2 “INDIVIDUAL DEVICE TEST RECORD”. This features a column for “Correctly Installed per Section 5, Verification Procedure - Field Devices”.

Notice what the Standard DOESN’T say! (Hint) Should the Verifier be ensuring the annunciator, the visual displays, and the controls are installed in accordance with CAN/ULC-S524-14 Clauses 5.2.1, 5.2.3, 5.2.4, 5.2.5 and 5.2.9? Most emphatically YES! Why, you ask, when the reference Clauses from the Installation Standard aren’t even mentioned in the Appendix “C” Report? The answer is clearly noted on the very first page of that same Appendix “C”:

C1 H “Installed in accordance with the design and CAN/ULC-S524 (Standard for Installation of Fire Alarm Systems).”

This is a powerful statement, and one that NO Verifier worth his salt should take lightly. It boils down to being a confirmation statement in which you are putting your professional qualifications, training, and experience ON THE LINE. You are vouching that the system complies with the requirements of the Installation Standard, the relevant Codes, and that all aspects of the system’s installation and operation aligns with the specific criteria to which it has been designed.

CAN/ULC-S536-13 (Standard for Inspection and Testing of Fire Alarm Systems) requirements

The first time any significant (to the technician conducting the annual testing) reference to INSTALLATION occurs in the Standard is Clause 4.6:

“Control unit or transponder and devices shall be inspected and tested as installed.”

So lets “skip” ahead to Section 6.4, entitled “ANNUNCIATORS, REMOTE TROUBLE SIGNAL UNITS, DISPLAY AND CONTROL CENTRES TEST AND INSPECTION”

This entire section is actually referenced as checklist items in the CAN/ULC-S536-13 Appendix “C” forms conveniently embedded in our Building Annual Life Safety Systems Test Form, which you can download from the FORMS page in our LIBRARY. Turn to page 8 of 30 (not a typo - there really are 30 pages). Terminology which relates directly to INSTALLATION occurs in:

C2.6 L “Displays are visible in the installed location”,

C2.7 L “Displays are visible in the installed location”, and

C3.2 “INDIVIDUAL DEVICE TEST RECORD”. There’s a column for “Correctly Installed”.

Notice what the Standard DOESN’T say! (Hint) Should the technician be checking that the annunciator, the visual displays, and the controls are installed in accordance with CAN/ULC-S524-14 Clauses 5.2.1, 5.2.3, 5.2.4, 5.2.5 and 5.2.5? NO, he doesn’t have to! The technician conducting an annual test isn’t Verifying the system to the Installation Standard. He should be checking for some specific criteria though (like proper mounting of the field device to make sure it’s not hanging from the wires, and is properly secured to a back-box). Keep in mind that CAN/ULC-S536 is largely a “blueprint” for the functional test of a fire alarm system that has already PASSED the Verification and Commissioning (and been accepted by the jurisdictional authority).

CAN/ULC-S561-13 (Standard for Installation and Services for Fire Signal Receiving Centres and Systems” requirements

Clause 1.2 states simply:

“The requirements of this Standard do not apply to the test, inspection, maintenance, installation and service of the building fire alarm system at the protected premises, as required in CAN/ULC-S524, Standard for Installation of Fire Alarm Systems; CAN/ULC-S536, Standard for Inspection and Testing of Fire Alarm Systems; and CAN/ULC-S537, Standard for Verification of Fire Alarm Systems.”

We’ll suggest that this Standard won’t address concerns regarding the installation of a fire alarm system annunciator, and we can ignore it for the purposes of this article.

CAN/ULC-S1001-11 (Standard for Integrated Testing of Building Life Safety Equipment and Systems) requirements

Section 1 of the Standard is entitled “SCOPE”, and reads:

“1.1 This Standard prescribes the methodology for verifying and documenting that all interconnections between systems provided for fire protection and life safety functions are installed and operating in conformance with their design criteria. Refer to Appendix A1.1.

1.2 This Standard is intended to satisfy the requirement for integrated testing in the National Building Code of Canada and the National Fire Code of Canada.

1.3 It is not the intent of this Standard that integrated systems testing ensure individual fire protection and life safety systems are functioning and installed in accordance with their design criteria or referenced Standards.”

In my professional opinion, the individual involved in the process of performing the Code mandated COMMISSIONING of a building’s life safety system should not only be familiar with all aspects of the buildings life safety equipment (and systems) installation, he should be REVIEWING the documentation integral to the testing of the individual systems as well. He must be knowledgeable about the various systems as well as the building’s design in order to formulate the testing plan that will satisfy the requirements of this Standard. He should, at the very least, be qualified to VERIFY a fire alarm system, which means he MUST be able to identify incorrectly installed or programmed equipment.

Canadian Electrical Code (CEC) CAN/CSA C22.1 - 2012 requirements

The two main Sections of the CEC referenced by the five Standards relevant to the INSTALLATION of a fire alarm system are Section 10, which has to do with grounding, and Section 32, which has to do with specific requirements for “Fire alarm systems, fire pumps, and carbon monoxide alarms”.

There isn’t any specific reference to fire alarm DEVICE installation in the Section 32 other than what’s required for conductors, wiring methods, equipment bonding, electrical supervision and current supply (the latter has to do with how the fire alarm system has to be powered).

Section 10, likewise, doesn’t include any specific reference to the physical installation of the fire alarm system. It does, however tell you about bonding the back box, and describes other acceptable grounding means and methods.

Section 12 is referenced in CAN/ULC-S524-14 (Standard for Installation of Fire Alarm Systems) and relates to wiring methods.

Section 2 covers some “General Rules” that DO vicariously relate to the installation of fire alarm system components.

“Rule 2-024 Use of approved equipment - Electrical equipment used in electrical installations within the jurisdiction of the inspection department shall be approved and shall be of a kind or type and rating approved for the specific purpose for which it is to be employed.”

This is a powerful Rule, and is at the very heart of the original focus of our investigation involving Mircom’s outdoor annunciator installations. Unfortunately, as it turns out, the colourful array of elephants in that room we mentioned, involves practically ALL of the fire alarm system manufacturers distributing products in Canada (and more specifically, the individuals responsible for the installation and it’s Verification). Please read on.

“Rule 2-026 Powers of rejection - Even though approval has been previously granted, the inspection department may reject, at any time, any electrical equipment under any of the following conditions:

(a) the equipment is substandard with respect to the sample on which approval was granted;

(b) the conditions of use indicate that the equipment is not suitable; or

(c) the terms of the approval agreement are not being carried out.”

Here’ the Rule that’s central to the conundrum this issue has raised, and which the local authorities are going to have to address.

If any electrical equipment (or component) has been approved for installation despite it’s not being listed for the specific purpose, there is no part of this Rule that would suggest an inspector can now reject that equipment (or component). Approval, as I interpret this Rule to read, requires the submittal of a sample of the product being installed, for examination. If what you find in the field substantially differs from the component that was originally submitted for approval, then you could legitimately exercise the power of REJECTION Rule 2-026 (a) provides.

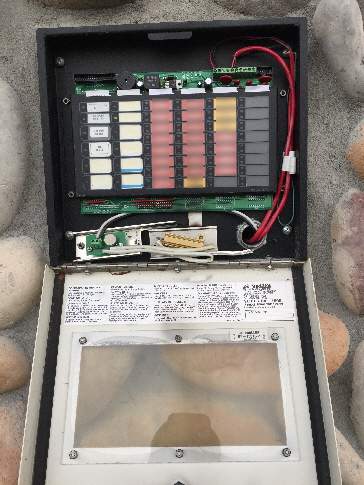

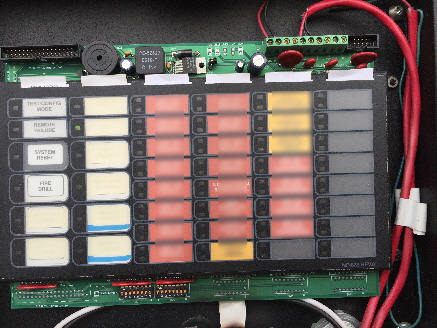

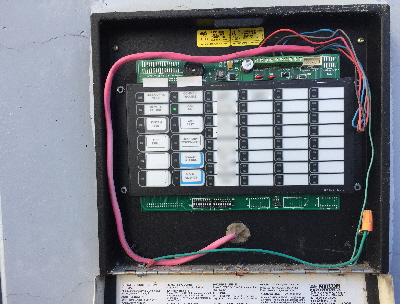

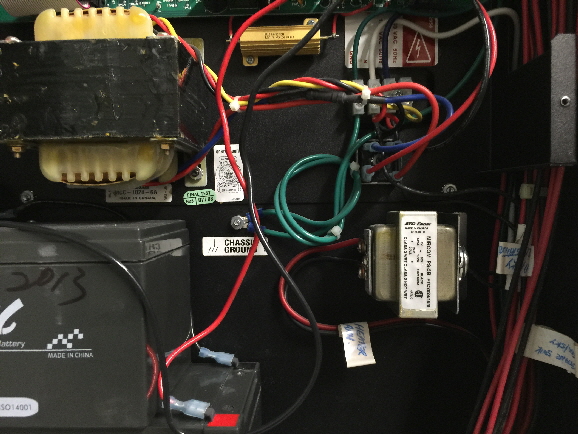

If the heater is not installed in the cabinet (as we’ve found with a number of the Mircom, Edwards, Simplex, and Notifier units), this would meet the rejection criteria in Rule 2-026 (b) that an inspection department could also enforce, the solution for which the manufacturer should be able to provide. So, an installation that utilized the Mircom BB-1001WP enclosure (to address that one elephant in the room everyone seems to be largely focused on), and which didn’t have a heater installed, or where the heater was incorrectly installed, (as illustrated in the photograph featured earlier), would, in our opinion, easily meet the rejection criteria in Rule 2-026 (b). Would correcting the issue by installing the heater assembly allow the unmarked back box to remain in use? Chances are that, with no heater installed, the potentially long-term exposure to the elements has compromised the integrity of the enclosure and it’s internal constituent components (this could easily be determined by a visual inspection). I would be strongly in favour of the more cautious approach, and recommend replacement of the entire assembly.

What about an identical installation with the heater already installed IN ACCORDANCE WITH THE MANUFACTURER’S PUBLISHED INSTALLATION INSTRUCTIONS? In this instance, I would suggest you cannot use this Rule to REJECT the installation. Why? If you’ve based your acceptance of the system on a Verification Appendix “C” Report and a Professional Engineer’s Signed and Sealed Schedule CB, and nothing has been substantially altered from that report (the equipment is being maintained in a fully operational condition), it could prove challenging to REJECT the installation retroactively, based and supported only by Rule 2-026 (b). I would respectfully suggest that you’re going to need more ammo if you are going to pursue the REJECTION option in this instance.

NOTE: Replacing (or modifications to) an annunciator enclosure is going to require an Electrical Permit (at the very least), and may trigger the requirement for a fire alarm Verification in accordance with Clause 7.8 of CAN/ULC-S537-13. This is detailed a little further on in this article.

To clarify my last point further, if the inspection department has identified that a particular product is NOT SUITABLE for installation within their jurisdiction (refer to Rule 2-024), then they have the legal grounds to REJECT that equipment even before it’s delivered to the site, and installed. (This is normally not the way it’s supposed to work, however. The electrical contractor is a key partner in the process and should be ensuring the equipment he installs complies, and is marked with, the relevant certification criteria required.) The inspection department cannot, (should not?) retroactively REJECT correctly installed (in accordance with the manufacturer’s instructions) equipment that has already been Verified and previously accepted, nor can you hold anyone personally responsible to bring that component into compliance (like the building owner, Verifier, manufacturer or Engineer), unless it presents a hazard to life or safety. And this is where another Rule might come into play which specifically addresses maintenance and operational issues of the installed equipment (this is Rule 2-300, which we’ll also be exploring in this article).

It should also be noted that issues involving maintenance and operation of building life safety equipment, according to the National Fire Code (2010) Division C, Sentence 2.2.1.1.(1), rests entirely with the building’s Owner (or the Owner’s authorized representative).

“Rule 2-100 Marking of equipment” expands upon the ability to properly identify approved equipment based on some very specific criteria (that’s further detailed in “Rule 2-400 Enclosures, type designations, and use” which we’ll cover later).

“Each piece of electrical equipment shall bear those of the following markings necessary to identify the equipment and ensure it is suitable for the particular installation.”

It then goes on to list what the equipment has to be marked with.

Does a previously accepted Verification Appendix “C” Report and a Professional Engineer’s Sealed Schedule CB constitute grounds for rejection of equipment that is NOT suitably marked? It would be difficult for me to suggest that it could, considering what I stated in my interpretation of Rule 2-026. It is extremely important for me to remind the reader, at this juncture, of an earlier DISCLAIMER, in which I stated that a jurisdictional authority may not subscribe to my interpretations of these Codes or Standards. Code interpretation is largely a subjective process which also relies on (and may be supported by) previous interpretations, or other documented precedents, which may have been rendered within the inspection department or the Fire Prevention Office. One man’s tea is another man’s coffee.

“Rule 2-300 General requirements for maintenance and operation

(1) All operating electrical equipment shall be kept in safe and proper working order.”

This Rule is going to give an inspection department the means to reject any outdoor (or indoor) mounted fire alarm system component if it’s not being maintained “in safe and proper working order” (the Rule applies to ALL electrical equipment). A number of enclosures (from a number of different elephants) which we documented the installation of, DID NOT have heater assemblies, were damaged by water ingress and/or prolonged exposure to the sun. The criteria for rejecting such an installation is fairly straight forward. It only involves a simple visual inspection, easily identified by the ASTTBC RFPT (or CFAA Certified Technician) performing the annual test of the fire alarm system (they are, after all, supposed to check (and document) that all the visual indicators function, and are correctly labelled, at each connected remote annunciator, aren’t they?).

Can a Fire Prevention Officer reference this Clause in a violation ticket? Unfortunately not. There is no reference to the Canadian Electrical Code C22.1 in the British Columbia (or National) Fire Code. There is a case to be made for the inspection department and the Fire Prevention Office to work cooperatively, however, to identify unsafe electrical installations and equipment. This would likely have to be further strategized at the jurisdictional level though.

It cannot be overstated, that the power to require the repair of a non-functional fire alarm component rests with your jurisdiction’s Fire Prevention Officer. Note that I stipulated “non-functional” and not “unapproved equipment”. Clause 6.3.1.1 of BCFC 2012 is entitled “Maintenance”, and reads:

“(1) Fire alarm and voice communication systems shall be maintained in operable condition at all times.”

We can split hairs on how a reasonable person should interpret operable condition.

If you can’t see the annunciator labels because they’re faded from exposure to the sun, it’s definitely not in operable condition, but simply replacing the labels would fix that. It wouldn’t reasonably meet the criteria for rejecting the entire installation.

If the heater were inoperable (or not installed) and/or the physical components of the annunciator were water damaged, I would suggest that this should constitute a failure to meet the operable condition criteria in the NFC (BCFC), which would make the installation subject to repair or replacement. To REPLACE an annunciator triggers a critical (and often overlooked) Clause in CAN/ULC-S537-13 (Standard for Verification of Fire Alarm Systems). Clause 7.8 reads:

“Where an existing fire alarm system control unit, transponder or annunciator is replaced with a new control unit, transponder or annunciator, it shall be verified in accordance with Section 5, Verification Procedures - Control Units and Transponders, and any existing devices shall be tested in accordance with Subsection 6.7, Field Devices of CAN/ULC-S536, Standard for Inspection and Testing of Fire Alarm Systems. (Refer to Clause 7.11.)”

(This is worded identically in Clause 6.8 of CAN/ULC-S537-04.)

You were looking for something with some meat in it; we’re serving up potatoes too.

Rule 2-400 Enclosures, type designations, and use (See Appendix B)

(1) For the purposes of this Code, the following designations of enclosures for electrical equipment other than motors and generators, shall be recognized for the intended use as specified in Table 65 and as follows:

(a) Type 1 for use indoors in ordinary locations;

(b) Type 2 for use indoors where the enclosure may be subject to drops of falling liquid due to condensation or other causes;

(c) Type 3R for use outdoors;

(d) Type 4 for use where the enclosure may be subject to direct streams of water;

(e) Type 5 for use indoors where the atmosphere may contain settling non-hazardous dust, lint, fibres, or flyings; and

(f) general-purpose enclosure for use indoors in ordinary locations.

(2) Other enclosure types tabulated in Table 65 shall be permitted to be substituted for those required in Subrule (1) provided that they

(a) offer a degree of protection at least equal to that required by Subrul (1) for the intended use, as indicated in Table 65; and

(b) are marked in accordance with Rule 2-402.

(3) Enclosures for equipment for use ina hazardous location shall be designed in accordance with Rule 18-052.

What powers does this Rule confer on the inspection department? None! It’s a Rule that establishes the criteria for acceptance for the inspection department and provides guidelines for identifying and confirming that the enclosure that’s installed complies with the intended use for the environment. It’s a Rule specifically intended for the qualified installer to ensure he provides a suitable enclosure to meet the environmental conditions where the equipment’s going to be located.

Table 65 expands on this Rule and is largely used to identify the specific environmental conditions the enclosure is designed to protect against. It’s called “Enclosure selection table for non-hazardous locations”. It lists hazards like “accidental contact with live parts”, “falling dirt”, “dropping and light splashing of non-corrosive liquids”, “hosedown and splashing water”, etc., and correlates these to the enclosure types.

What rating should an outdoor fire alarm annunciator housing be constructed to? Many would suggest Category 4 which means it would be rated to protect the annunciator from “hosedown and splashing water”. This is also categorized as NEMA 4 (NEMA has no official standing in Canada). In our opinion, Category 3 could also apply but wouldn’t offer much in the way of protection against “hosedown and splashing water”. Contractors should consider installing the higher rated enclosure if you’ve been given the choice between the two mentioned.

And now that we’ve served the meat and the potatoes, here’s a healthy helping of gravy.

“Rule 2-402 Marking of enclosures

(1) Except for general-purpose enclosures, all enclosures described in Table 65 shall be marked with a type or enclosure designation.

(2) In addition to the type or enclosure designation specified in Subrule (1), enclosures shall be permitted to be marked with an Ingress Protection (IP) designation.”

And this is precisely where the installer has the opportunity to ensure his enclosure complies with the environmental conditions and hazards it’s going to be exposed to. It’s also a key INSPECTION ITEM that should become part of any related processes that follow, whether it’s the Verification, Commissioning, or Annual Inspection.

ONE LITTLE ELEPHANT

Many authorities and fire equipment service professionals have loudly voiced opinions (and jumped on the band-wagon) questioning the use of Mircom’s TH-101 heater, because it’s not properly labelled or listed. Since the submission of our report to ULC, a detailed investigation of this product’s application, by Mircom’s Vice-President for Engineering, Laurie Eisner, has concluded that a listing (or approval mark) is not required, so I’m going to change the wagon’s music just a smidge by introducing a slightly more classical tune (from CEC 22.1-12):

“Rule 16-222 Equipment located on the load side of overcurrent protection, transformers, or current-limiting devices for Class 2 circuits (see Appendix B)

(1) Equipment located on the load side of overcurrent protection, transformers, or current-limiting devices for Class 2 circuits shall

(a) For Class 2 circuits operating at not more than 42.4 V peak or dc, be acceptable for the particular application; and

(b) For Class 2 circuits operating at more than 42.4 V peak or dc, be arranged so that no live parts are accessible to unauthorized persons.

(c) Notwithstanding Subrule (1), lighting products, electromedical equipment, equipment for hazardous locations, and thermostats incorporating heat anticipators shall be approved.”

My examination of the TH-101 confirmed that it employs a simple thermostat (with no heat anticipator) and is powered through a Class 2 transformer. The unit would also qualify as an “ancillary device” not powered by the fire alarm control. Unlike a magnetic door holder (also an “ancillary device”), the annunciator heater is more mission critical, and we would recommend that the outputs of the transformer supplying power to the unit be supervised by the fire alarm system in all new installations (as we have suggested in our Report to ULC). Should this requirement (if adopted as part of the equipment’s amended installation criteria) be retroactive? It would be my suggestion that if it already forms part of an accepted installation that is being adequately maintained and serviced (as evidenced by previous inspection reports and/or a simple visual examination of the annunciator enclosure’s internal components), and is installed in accordance with the published installation instructions, then NO. What SHOULD be addressed however, is the often illegal installation of the transformer powering the unit.

|

RECOMMENDED ADDITIONAL INSTALLATION, VERIFICATION AND INSPECTION PROCEDURES

It’s obvious that outdoor mounted fire alarm annunciators require some additional installation, Verification, and testing criteria that, while not specifically identified in the relevant Standards, are incumbent upon the Verifier (as well as the technician performing the annual inspection) of the system, to identify, understand and properly implement.

The two inspection Standards that fire protection equipment service technicians in Canada are using today are not perfect, but they do represent the currently required MINIMUM testing criteria. It’s interesting to note that many service agencies often suggest that technicians can compromise whole Sections of them, excusing the resulting bad practice with nonsensical statements like the customer didn’t pay for that part of the test, or sensitivity testing of smoke detectors is an optional extra to the quotation. The National Building and Fire Codes make no allowances for optioning (or ignoring) Sections of the relevant testing Standards (neither do the Standards for that matter). As a professional technician, when you apply your tag to the system, and sign your name on the bottom of the Appendix “C” (or “E”) test report, you aren’t merely suggesting that the requirements of the relevant Standards have been met, you are CLEARLY STATING THAT THEY HAVE!

Installation

The manufacturer provides detailed instructions for the installation, connection, and wiring of their respective remote annunciator products. Most require separate wire pairs for annunciator power and the serial data connection. An installer should open the installation instructions and READ THEM! Non-compliant installations will likely NOT be accepted by Verifiers that have the knowledge to recognize that additional testing criteria is going to be required. DON’T take the chance of having your installation fail for something as dumb as not following the directions!

The annunciator heater (if needed to ensure compliance with the enclosure’s listing) also has some specific installation requirements. We would suggest that the power input for the heater be supervised (at the very least at the transformer’s output terminals). Some jurisdictions may insist that the only correct supervisory method is achieved from the actual heater terminals (at the end of the wire run). Check with your inspection department if the manufacturer’s installation instructions aren’t clear. Exercise caution, and some common sense, when you’re interconnecting a supporting field device to the supervisory connections of the heater (or related relay).

The transformer powering the annunciator may not have to be on a dedicated circuit, but you should consider reserving one for the purpose, particularly if you’re powering more than one heater. MARK THE BREAKER controlling the heater, or heater transformer and provide a locking device to prevent it being turned off inadvertently!

Verification

Where should a Verifier record the installation and testing of the correctly installed annunciator heater? What testing/inspection should he perform on the annunciator (over and above what’s already detailed in Appendix Items C5.8 and C5.9)? Note: All referenced Appendix Cx.xx items are from CAN/ULC-S537-13.

- Check that the enclosure is not damaged, the grommets and seals are all intact and that the labels (ALL OF THEM) are properly displayed and are legible. Make sure the installer has adhered to the applicable mounting height requirements in CAN/ULC-S524 (Standard for Installation of Fire Alarm Systems), and that the manufacturer’s published installation instructions have been followed and correctly applied (i.e. wiring type, wire gauge, wire entry, heater location).

- Check to ensure that the annunciator interior is clean and undamaged (i.e. no scorch marks from the heater).

- List the heater as an ancillary device (not controlled by the fire alarm system power) on the Ancillary Device Circuit Test in C5.12.

- Identify the type of supervisory device that’s being employed and include this on the C6.1 Field Device Testing - LEGEND page.

- Transfer the “AD” listed in Item 2 to the C6.2 Individual Device Record page and note its location. If the fire alarm system you’re Verifying happens to be a fully addressable unit, you’re also going to have the list the associated remote initiating module on a separate line. If there’s an associated end-of-line resistor plate (or EOL relay), you’re going to have to record that as a line item (along with its location) on the C6.2 form as well. Follow the procedures for field testing all of these devices and record the results in the appropriate columns.

- Check to ensure the correct transformer has been installed and is properly terminated.

- Check to ensure that the power to the transformer is NOT shared with the fire alarm control’s primary power supply connection. If you can’t determine where it’s being powered from, there is a way to ensure that the source is NOT part of the main power to the FAS. First, measure the voltage across the transformer’s output. Then TURN OFF the power to the fire alarm panel. If there is no voltage present at the transformer’s secondaries, the installation fails and the contractor will have to make appropriate corrections. If the breaker controlling the heater isn’t properly marked, advise the installer to “make it so”, using your best Captain Jean-Luc Picard impression. If the fire alarm control doesn’t indicate a supervisory fault for the zone labelled “annunciator heater” or “annunciator heater power”, the installation fails and the contractor is going to have to make some adjustments. If there IS NO ZONE labelled “annunciator heater” or “annunciator heater power”, the installation fails and YOU’RE going to have to confirm the connections and make some adjustments (which may also require some assistance from the installer). Turn the power back ON and reset the system.

- Check to ensure that there’s power at the annunciator heater. Yes, this will require you to walk outside (please ensure you dress for the weather)!

Inspection

Where should a technician record the testing of the installed annunciator heater? What testing should be performed on a outdoor mounted annunciator on an annual basis (over and above what’s already detailed in Appendix Items C2.6 and C2.7)? Note: All referenced Appendix Cx.xx items are from CAN/ULC-S536-13.

- Check that the enclosure is not damaged, the grommets and seals are all intact and that the labels (ALL OF THEM) are properly displayed and legible. If you spot anything unusual, record it on the C2.15 form and take a picture with your hand-held device (this includes scorch marks around the heater or that may be visible on any of the internal components).

- List the heater as an ancillary device (not controlled by the fire alarm system’s power supply) on the Ancillary Device Circuit Test in C2.12.

- Identify the type of supervisory device that’s being employed and document this on the C3.1 Field Device Testing - LEGEND AND NOTES page.

- Transfer the “AD” listed in Item 2 to the C3.2 Individual Device Record form and identify its location. If the fire alarm system you’re inspecting happens to be a fully addressable unit, you’re also going to have the list the associated remote initiating module on a separate line. If there’s a separate end-of-line resistor plate, you’re going to have to record that as a separate line item (along with its location) on the C3.2 form as well. Follow the procedures for field testing all of these devices and record the results in the appropriate columns.

- Check to ensure the correct transformer has been installed.

- Check to ensure that the power to the transformer is NOT sharing the fire alarm control’s primary power supply connection. You’ll have to measure the voltage across the transformer’s output, first, then TURN OFF the power to the fire alarm panel. If there is no voltage present at the transformer’s secondaries, note this on your report as a deficiency (yes, this qualifies as one). If the fire alarm control doesn’t indicate a supervisory fault for the zone that’s labelled “annunciator heater” or “annunciator heater power”, the system doesn’t necessarily fail. Record this as a REMARK in C2.15. When you tag the panel, check the Additional Work Required and the See log and Report (if you’re still working with the older version ASTTBC inspection tags). Turn the power back ON and reset the system.

- Check to ensure that there’s power at the annunciator heater. Yes, this will require you to walk outside (please ensure you dress for the weather).

|

|

|

QUESTA NON È LA FINE!

Are changes to the Standards going to be made to close the gaps identified in this article? I would like to suggest that some are certainly going to be considered, but until they actually do manifest in an actionable Clause, it’s up the professional practitioner to recognize the gaps, make appropriate adjustments, and SHARE this information with the community at large. As an individual, you have but one voice. As a community (a union of professionals, if you will), you’ve just become a chorus.

Have I missed anything? Oh yeah... While this article started out to focus on a particular manufacturer’s outdoor mounted annunciators, it’s turned out to be just the opening steps in a genuinely eye-popping journey of discovery. There are some extraordinary people I have to thank in helping me put this all together, but first things first.

This article is far from finished. Please consider it a work in progress. This also explains why this section features an Italian phrase for “this is not the end”. We will be updating it with more information as we receive and process it. We are still very much involved in ongoing investigations and continue to remain engaged in very active discussions with owners, manufacturers, technicians, installers, Engineers, designers, and authorities across Canada. Please ensure you check back often!

I strive to present relevant facts and details related to any investigation or Code/Standard interpretation in as objective a manner as possible. It would be remiss of me, however, not to mention the fact that management and staff at the Mircom Group of Companies have been amazingly cooperative in providing the information necessary to ensure no stone remains unturned. My frequent interactions with Mircom’s senior executive over the course of this last week has provided me with a far greater appreciation and understanding of the daily challenges a manufacturer of life safety products in Canada has to face. It’s also served to increase my confidence in our Canadian equipment certification programs and reinforced my respect for the people that form the community of committed, knowledgeable life safety professionals that I consider myself privileged to be part of.

I am grateful to the following individuals for their assistance and encouragement in the production of this article:

Arkady Tsisserev

Mark Falbo

Jason Falbo

Laurie Eisner

Alan Taaffe

Dave Clark

Wayne Doucette

![]()

SUGGESTED ADDITIONAL READING

Need more information? Check out our HANDBOOK sale!

Our new series examines the Fire Alarm Verification process in depth.

CAN/ULC-S536 DO’S AND DON’T’S - Special Reports

Check out some special TOOLS!

Catch up on important Bulletins.

Mircom Group of Companies website is located at http://www.mircom.com .

Potter Electric Signal Company website is located at https://www.pottersignal.com/ .

Chubb Edwards website is located at http://en.chubbedwards.com/Pages/Home.aspx .

Tyco Integrated Systems (Simplex) website is located at https://www.tycoifs.ca/en .

Notifier Canada (by Honeywell) website is located at https://www.notifier.com/Pages/default.aspx .

Firelite Alarms (by Honeywell) website is located at http://www.firelite.com/en-US/Pages/default.aspx .

STI-USA website is located at http://www.sti-usa.com/ .

![]()

QUICK LINKS!

AHJ Training Courses are being offered by two (2) Canadian national associations:

- The Canadian Fire Alarm Association (CFAA) - Please visit their website (link below) for information on one being held in your area.

- The Fire Technicians Network (FTN) - Feel free to visit our Training Centre for available dates and cities! To make arrangements for us to present our two day Course Programme in YOUR municipality, please Contact Us for details!

Canadian Fire Alarm Technician Certification:

- The Canadian Fire Alarm Association (CFAA) website is located at http://www.cfaa.ca .

- Learn more about a Fire Protection Technician Certification Programme that sets a new Canadian Benchmark for our industry!

Fire Protection Equipment Technicians (Extinguisher Service):

- Transport Canada website is located at http://wwwapps.tc.gc.ca/saf-sec-sur/3/fdr-rici/cylinder/requalifier.aspx

- Warnock Hersey (Intertek) website is located at http://www.intertek.com/iqp/ahj/

Fire Protection Equipment Technicians (British Columbia):

- The Applied Science Technologists and Technicians of British Columbia (ASTTBC) website is located at http://www.fireprotection.asttbc.org

![]()

INTERESTED IN COMMENTING ON THIS ARTICLE? QUESTIONS? GOT A STORY? SOMETHING OF INTEREST AND/OR NOTE-WORTHY?

The Fire Technicians Network

+1 (888) 340-3473

“We are not a professional union, but together, we are a union of professionals!”

What we’re all about!

We are not affiliated with ASTTBC, CFAA, CANASA, NFPA, NAFED, or NICET (although we encourage you to explore and objectively evaluate the benefits associated with supporting their individual efforts). Membership in the Fire Technicians Network is entirely voluntary. Are you up to the challenge of demonstrating your commitment to public safety and the highest standard of professional practice?

Copyright © 2007 - 2020 The Fire Technicians Network. All Rights Reserved