Special Reports & Feature Stories!

CAN/ULC-536-13 (Canadian Annual Fire Alarm Inspection Standard)

DO’S AND DON’T’S

DEBUNKING THE MYTHS & COMMON MISCONCEPTIONS ABOUT END-OF-LINE TESTING!

By Frank Kurz

Common Myths and Misconceptions:

#1 - I don’t have to test end-of-line resistors.

#2 - I don’t have to test end-of-line power supervision relays.

#3 - End-of-Line resistors don’t have to be mounted on a plate.

#4 - I don't ever have to perform voltage drop tests.

![]()

Some Battlefield Examples:

Example #1:

|

This picture depicts a common installation error for end-of-line resistor terminations (they’re “floating” free inside a Listed enclosure). What makes this installation unique is the rather interesting way the “installer” decided to use a Mircom terminal strip. You’ll note the violet and yellow wires are crimped into the connector while the end-of-line resistor is terminated under the screws. The other resistor (at the end of the second set of violet and yellow wires at the lower right) is terminated in the more “traditional” method which employs wire nuts. It’s still wrong!

Example #2:

|

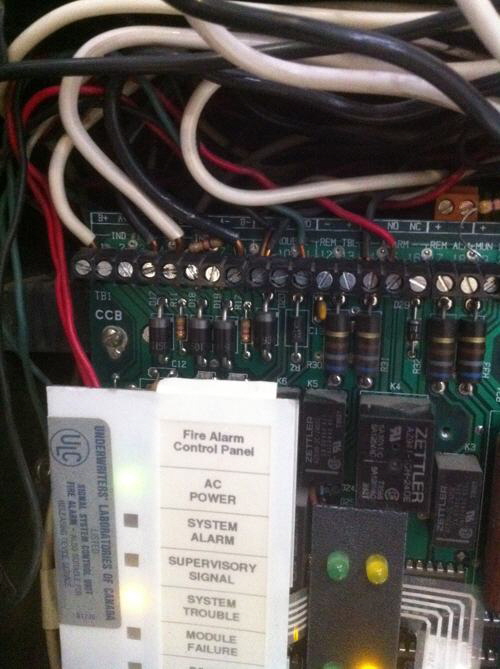

This is a Notifier 5000 system. The Notification Appliance Circuits are the first eight terminals of the common control board. Terminals 1 & 4 are NAC 1 (IND 1) for Class “B”. For a Class “A” circuit, terminals 2 & 3 provide the alternate path to the notification appliances. Terminals 5 & 8 are NAC 2 (IND 2) for Class “B”. As you can see there’s a resistor across these terminals in addition to the field wiring. We found the end-of-line plate still mounted in a hallway next to a non-functional bell.

![]()

INSPECTION STANDARD REQUIREMENTS:

Let's review the relevant sections of CAN/ULC-S536-13 as they apply to end-of-line resistor testing. Section 6.7.11 is entitled CIRCUIT END-OF-LINE DEVICE and it states:

“6.7.11.1 Each input circuit end-of-line device shall be tested for open circuit fault, short circuit fault and ground fault conditions. The results shall be recorded in the Inspection Report. Refer to Appendix C3.2.”

“6.7.11.2 Each output circuit end-of-line device shall be tested for open circuit fault, short circuit fault and ground fault conditions. The results shall be recorded in the Inspection Report. Refer to Appendix C3.2.”

“Shall” is an imperative, folks. It’s mentioned FOUR times in these clauses.

![]()

INSTALLATION STANDARD REQUIREMENTS:

Let's review the relevant sections of CAN/ULC-S524-14 as they apply to end-of-line resistor installation requirements. Section 10.1 is entitled END-OF-LINE DEVICES and it states:

“10.1.1 Except as permitted by Clause 10.1.2, end-of-line devices for electrical supervision shall be located in a separate enclosure, installed less than 1800 mm above finished floor level measured from the centre of the end-of-line device, and located beyond the last device in the circuit or terminated in a control unit or transponder.

10.1.2 End-of-line devices for one field device on a circuit may be located within that field device provided that the end-of-line voltage can be tested.

10.1.3 End-of-line devices shall have an identifying label securely attached to the front of the cover plate, listing the zone served.

10.1.4 Where end-of-line devices are located witin a field device, as permitted by Clause 10.1.2, an identifying mark visible after installation shall be affixed to the field device.”

Notice how there’s only one “may” in this entire section and it has to do with the location of an end-of-line device connected to a single field device on a circuit.

![]()

FIRE CODE REQUIREMENTS:

Let's review the British Columbia Fire Code Division “B” Part 6. Because it's based on the National Fire Code I'm pretty sure the wording and references are good for other provinces. It is where we'll find:

“6.3.1.2 Inspection, Testing and Maintenance

1) Fire alarm systems shall be inspected and tested in conformance with CAN/ULC-S536, “Inspection and Testing of Fire Alarm Systems.”

2) Fire alarm and detection system components shall be accessible for purposes of inspection or maintenance.”

There’s that pesky little “shall” again. What do these clauses mean? Simple! You are in violation of the Fire Code if you are not testing a fire alarm system’s components properly - IN ACCORDANCE WITH THE STANDARD!

![]()

DISPELLING THE MYTHS (AND A WARNING FOR TECHNICIANS CONTEMPLATING PRACTICE ON THE DARK SIDE):

End-of-line resistors and power supervision relays are devices employed to supervise the wiring between a fire alarm control panel (or an addressable module) and the connected conventional field devices. The term “end-of-line” describes not only the device, but where it should be mounted (at the “end” of, or as the last device in, a circuit). As the “last device”, it’s also the perfect place to perform the voltage drop test required by another Standard, CAN/ULC-S537-13 (Standard for Verification of Fire Alarm Systems). The annual test likely won’t discover an illegal “T” tap on a conventionally supervised device circuit (the VERIFICATION is supposed to pick that up).

Making sure all of the Verification documentation is on hand should be part of what you should be doing before you even start your annual inspection. Our building annual inspection form (available from our FORMS page) actually lists the documentation you should be checking for. The latest edition of the Fire Alarm Inspection Standard (CAN/ULC-S536:2019) has some significant changes .

Many managers of fire service companies promote (often encourage) the use of “short cuts” (illegal practice) through special incentives which they sometimes offer to their “less savvy” (or equally unethical) technicians. End-of-line resistor and smoke detector sensitivity testing are usually the first casualties in the battle to stay competitive. Incentives to circumvent their proper testing could take the form of monetary “bonuses” or verbal accolades (“You’re our STAR tech!”) if you’ve managed to complete the testing in a project faster than the-guy-who-did-it-last-year.

Before we “wax poetic” on the lack of ethics required to accept such dubious rewards, let’s take a very quick look at some of the FINE structures established by various jurisdictions across Canada for violations of the published Provincial Fire Code.

First off, you’ll find this section of the National Fire Code in almost every municipal Fire Bylaw I’ve reviewed:

Section “C” is entitled “Administrative Provisions”.

Clause 2.2.1.1 states:

“Responsibility

1) Unless otherwise specified, the owner or the owner’s authorized agent shall be responsible for carrying out the provisions of this Code.”

Clause 2.2.1.2 states:

“Records

1) Where this Code requires that tests, inspections, maintenance or operational procedures be performed on a fire safety system, records shall be made and the original or a copy shall be retained at the premises for examination by the authority having jurisdiction.

2) The initial verification or test reports for each system shall be retained throughout the life of the systems.

3) Records of tests, inspections, maintenance or operational procedures undertaken after the initial tests referred to in Sentence (2) shall be retained so that at least the current and immediately preceding records are available.

4) Notwithstanding the conditions stated in Sentence (3), no record shall be destroyed within two years of having been prepared.”

Fine Schedule (we’ll be adding more as the information is provided):

|

It is both the duty and the responsibility of every technician engaged in the service, testing, and inspection of a fire alarm system to ensure that what they’re doing complies with the relevant Codes and Standards. It goes without saying (but I’ll say it anyway) that non-compliance carries with it the possibility of hefty monetary penalties and possible incarceration (which could mean a criminal record). As the solely appointed “agent” of the Owner, YOU, yes, you (the guy performing the inspection) becomes directly responsible to ensure that the service you provide is above reproach. Agents of your employer (e.g. service manager, manager) may decide to justify “under-cutting” the competition to get the job by offering the suggestion that the testing is “not required” because no one else is doing it. There is however, no way you should be accepting responsibility for such substandard work (or cut the corners your employer may suggest) simply because there no way to justify any departure from the Testing Standard. If what you’re being asked to do (or submit in the way of paperwork) doesn’t comply with the Standard, it is YOU who will bear the ultimate responsibility. Your signature, after all is said and done, is on the report (and on any of the tags affixed to the fire protection equipment).

YOU WILL (EVENTUALLY) GET CAUGHT!

![]()

TIPS AND RESOURCES:

We review the correct procedure (required by ASTTBC’s Practice Guideline under the heading Preparation) that you should follow prior to performing any life safety equipment testing in this FAQ.

There is additional information regarding the Annual Testing of Fire Protection Equipment located in our FAQS page.

![]()

Questions?

Call or email us!

|

|

|

||

|

|

|||

|

|

|

The Fire Technicians Network

+1 (888) 340-3473

“We are not a professional union, but together, we are a union of professionals!”

What we’re all about!

We are not affiliated with ASTTBC, CFAA, CANASA, NFPA, NAFED, or NICET (although we encourage you to explore and objectively evaluate the benefits associated with supporting their individual efforts). Membership in the Fire Technicians Network is entirely voluntary. Are you up to the challenge of demonstrating your commitment to public safety and the highest standard of professional practice?

Copyright © 2007 - 2021 The Fire Technicians Network. All Rights Reserved