|

Out of an abundance of caution, we are providing some additional information for building owners and/or contractors contemplating the installation and use of the Larrstep EEL-1 product on a fire alarm or life safety system. Please do not infer that we are in any way suggesting that you should NOT consider using it to help reduce the annual testing time for your project. We support Canadian industry and invention. UL and ULC should, in our opinion, actually investigate the product further and produce a compatibility chart so the device is not inadvertently installed on a system where the key-switch may be damaged or the operation of the fire alarm circuit it’s installed on, compromised. Despite its being advertised as a “universal” solution, you must install any fire alarm field device in accordance with CAN/ULC-S524-06(14), the published installation instructions, and observe all precautions, warnings, and printed limitation(s).

Update: (August 31, 2018) We have been informed by Mr. L. Geoghegan, President of Larrstep Inc., that the switching current of the keyswitch has recently been re-evaluated and increased to 100 mA (0.1 Amps) from the originally certified maximum of 50 mA. This information is available on their website. Our bulletin has been amended accordingly.

|

|

|

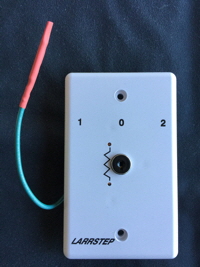

Larrstep EEL-1

|

|

Two Important Precautions (applies to ALL fire alarm system components and controls in Canada)

- With the exception of replacing a damaged (or non-functional) system component, the retrofit installation of any fire alarm field device is considered a modification of your fire alarm system and, as such, consultation with your local jurisdictional authority is advised. An Electrical or Building Permit (or both) may be required and the installation should be performed by a qualified electrician. These additional costs should also be factored in to your decision to deploy the device.

- Replacement (or the retro-fit installation) of any fire alarm field device in Canada is subject to a Verification in accordance with Section 7 of CAN/ULC-S537-13 (Standard for Verification of Fire Alarm Systems).

Larrstep Deployment Guidelines

- The Larrstep EEL-1 key-switch is limited to a maximum switching current of 100 mA (0.1 Amps). Fire alarm system control units utilize a variety of input and output circuits employing a wide range of current carrying capacities depending on the manufacturer (the model of the control panel and/or module). We’ve provided some examples in Table A below. If the switching current on the circuit equals or exceeds 100 mA, you CANNOT install the product.

- Larrstep EEL-1 should not be located in an unconditioned space (unheated parking garages, sprinkler rooms, etc.).

- The Larrstep EEL-1 should not be installed to test Data Communication Link (Signalling Line Circuit) isolators because of the high switching currents involved, even though it is advertised as an “isolator tester” (see Table “A” below).

- The unit cannot be used to test the shorting current on a Notification Appliance Circuit (NAC) which can easily exceed the maximum rated switch current of 100 mA. This includes isolated suite sounders because you may be initially switching the entire NAC supervisory (or alarm) circuit current and not just the isolated room. In Canada, all notification appliance devices must be supervised for opens in the circuit (including those installed on the isolated side of suite sounder isolators).

- You cannot use this product to test power or audio buss riser isolators.

|

Table Legend N/A means Not Available

|

|

Table A - Maximum Switching Currents On Short1

(Updated July 19, 2018)

|

|

DCL / SLC Loop

|

|

Panel Manufacturer & Model Number

|

Max. Current

|

Normal Current

|

|

Chubb Edwards iO 64 / iO 500

|

500 mA

|

60 mA

|

|

Fireguard IQ-500

|

250 mA

|

N/A

|

|

Firelite ES-200X

|

400 mA

|

100 mA

|

|

Firelite ES-50X

|

200 mA

|

100 mA

|

|

Firelite MS-9600LSC

|

400 mA

|

100 mA

|

|

Mircom FX-2003-6DS / FX-2003-12DS

|

400 mA

|

N/A

|

|

Notifier AM2020 (LIB-200 / LIB-400)

|

200 mA

|

100 mA

|

|

Potter PFC-6800 (includes SLCE-127 expanders)

|

56.055 mA

|

N/A

|

|

Siemens BC8001A

|

250 mA

|

N/A

|

|

Siemens FireFinder-XLS

|

375 mA

|

N/A

|

|

Siemens MXL/MSLV4 MMB-2

|

66 mA

|

66 mA

|

|

Simplex / Tyco IS6 4100ES IDNet Card

|

350 mA

|

N/A

|

|

Initiating Circuits (EOL Supervised)

|

|

Panel Manufacturer & Model Number

|

Max. Current

|

Normal Current

|

|

Chubb Edwards “QS” ZA8-2 / ZB16-4

|

75.9 mA

|

N/A

|

|

Edwards 6616 / 6632 B351 (per circuit)

|

115 mA

|

5.8 mA

|

|

Edwards 6616 / 6632 B352 (per circuit)

|

10.8 mA

|

3.7 mA

|

|

Edwards 6616 / 6632 B354 (per circuit)

|

115 mA

|

5.8 mA

|

|

Chubb Edwards SIGA-CT1

|

0.00025 mA

|

0.0004 mA

|

|

Chubb Edwards SIGA-CT2 (per circuit)

|

0.000396 mA

|

0.00068 mA

|

|

Chubb Edwards SIGA-UM (2-wire smoke module)

|

17 mA

|

2 mA

|

|

Chubb Edwards SIGA-MAB (2-wire smoke module)

|

17 mA

|

2 mA

|

|

Fireguard IQ-400 Series

|

45 mA

|

15-30 mA

|

|

Fireguard IQ-515MZ (2-wire smoke module)

|

60 mA

|

5 mA

|

|

Firelite MS-5UD / MS-10UD

|

40 mA

|

N/A

|

|

Mircom FA-103 / FA-106

|

50 mA

|

3 mA

|

|

Mircom FA-101T, FA-102T, FA-1025T

|

21 mA

|

N/A

|

|

Mircom FA-1000 (includes DM-1008)

|

50 mA

|

3 mA

|

|

Potter CIZM-4 Expansion Module

|

50 mA

|

2.4 mA

|

|

Potter IDC-6 Zone Adder Module (per circuit)

|

47 mA

|

2.5 mA

|

|

Potter PFC-4064

|

47 mA

|

2.5 mA

|

|

Potter ZA-42 Zone Adder Module (per circuit)

|

50 mA

|

3 mA

|

|

Potter PFC-6006

|

32 mA

|

2.5 mA

|

|

Siemens FireFinder -XLS CDC-4 (per circuit)

|

175 mA

|

4 mA

|

|

Siemens MXL/MSLV4 CZM-1B6 (with ISI-1)

|

93 mA

|

N/A

|

|

Siemens MXL/MSLV4 CZM-4 (per circuit)

|

180 mA

|

N/A

|

|

Siemens FS-TRI-S4, FS-TRI-D4 (per circuit)

|

0.8 mA

|

0.5 mA

|

|

Siemens TRI-B64 (per circuit)

|

N/A

|

1.5 mA

|

|

Simplex / Tyco IS6 4100 / 4120 Zone Interface Cards

|

60 mA

|

3 mA

|

|

Simplex / Tyco IS6 4001 Zone Expansion Modules

|

60 mA

|

N/A

|

|

System Sensor CZ-6(A)2 (per circuit)

|

90 mA

|

N/A

|

|

System Sensor IM-10(A)3 (per circuit)

|

1 mA

|

N/A

|

|

System Sensor M500DMR1A9 (per circuit)

|

0.00045 mA

|

N/A

|

|

System Sensor M500MAB8

|

0.0004 mA

|

N/A

|

|

System Sensor M501MA7

|

0.0004 mA

|

N/A

|

|

System Sensor M502MA5

|

92 mA

|

10 mA

|

|

|

Table A Notes:

|

|

1

|

Reference to the specific system manufacturer’s Installation and Operating Instructions was made in order to compile this Table. Additional manufacturers will be added as more information becomes available.

|

|

2

|

Equivalent OEM Modules: Firelite MMF-302-6(A), Mircom CZ-6(A), Notifer XP6-MA(A)

|

|

3

|

Equivalent OEM Modules: Firelite MMF-300-10(A), Mircom IM-10(A), Notifier XP-10M(A)

|

|

4

|

May also be labelled as Cerberus/Pyrotronics

|

|

5

|

Equivalent OEM Modules: Firelite MMF-302(A), Mircom MIX502MA(A), Notifier FZM-1A(A)

|

|

6

|

Now Johnson Controls

|

|

7

|

Equivalent OEM Modules: Firelite MMF-301(A), Mircom MIX501MA(A), Notifier FMM-101(A)

|

|

8

|

Equivalent OEM Modules: Firelite MMF-300(A), Mircom MIX500MAB(A), Notifier FMM-1(A)

|

|

9

|

Equivalent OEM Modules: Firelite CDRM-300(A), Mircom MIX500DMR1A(A), Notifier FDRM-1(A)

|

|

Disclaimer: Some products listed in Table A may not be suitable (or listed) for use in Canada. Additional agency listings may also apply to your specific jurisdiction. It is incumbent on the installation or equipment service provider to ensure that any fire alarm device that is installed is compatible with the system and is also approved for use in the jurisdiction!

|

|

For those systems not included (or where specific currents were not provided in the manufacturer’s specifications for inclusion) in Table A, you can manually check the switching current on an initiating circuit (or Data Communications Link / Signalling Line Circuit). We recommend using a Fluke Model 117 meter which has a “min / max” setting and a good, solid response time. It is important to note that Table A was produced from information located in the respective manufacturer’s published Installation and Operating Instructions. Actual empirical measurements may differ slightly from the published values in Table A owing to the inherent discrepancies you may encounter when using any commercially available, non-calibrated measuring instrument. The fire alarm manufacturer’s published instructions is the reference used to confirm compatibility for all fire alarm field devices and must always be followed.

Determining Switching Current for an Input Circuit or Data Communications Link Loop Controller

(You can also use this method for a notification or output circuit where the current is limited to a maximum of 5 Amps but we would recommend you only perform this in normal “supervisory” mode and not while the circuit is in alarm.)

Follow these procedures:

- Disable the notification and output circuits.

- With your meter set to read current (Amps), manually select a current range between “zero” (0) and 1 Amp.

- Locate the circuit’s end-of-line resistor.

- CONFIRM that this is an initiating circuit end-of-line and not one for a notification circuit. Do this by introducing a short across the resistor (your required “short” test). If it’s an initiating circuit, you will cause an alarm on the system.

- Reset the system.

- Place your meter leads across the end-of-line. If the momentary current you read is above 100 mA (0.1 Amps), you CANNOT install the Larrstep EEL-1. If your meter has a “min / max” settings button (and displays an out-of-range message), you may wish to activate this feature after manually selecting the next highest range, and retest the circuit to confirm your results.

- Reset the system following completion of your tests; and

- Don’t forget to re-enable your notification and output circuits!

Canadian Verification Guidelines (CAN/ULC-S537-13)

Individuals engaged in performing a Verification of newly installed Larrstep EEL-1 end-of-line plates must ensure that the shorting current on the circuit under test does not exceed 100 mA. It is equally important to ensure that the normal “supervisory” circuit current does not exceed 100 mA as the “open circuit” test position could also pose a damage risk for the key-switch. The product cannot be used on any notification appliance circuit or indicating circuit (NAC or IDC) as the short current when the fire alarm system is in ALARM can easily exceed one Amp (or more) depending on the number of audible and visible signalling devices that are connected. The Verifier must confirm that the product is installed correctly in accordance with the published installation instructions which should detail its suitability for the intended use, as well as the safe operation of the device. Despite it being marketed as an isolator tester, its use in this role must also be carefully evaluated (see Table A).

|